Polyworks Inspector – The 3D dimensional analysis and quality control solution to gain control of your product engineering and manufacturing process!

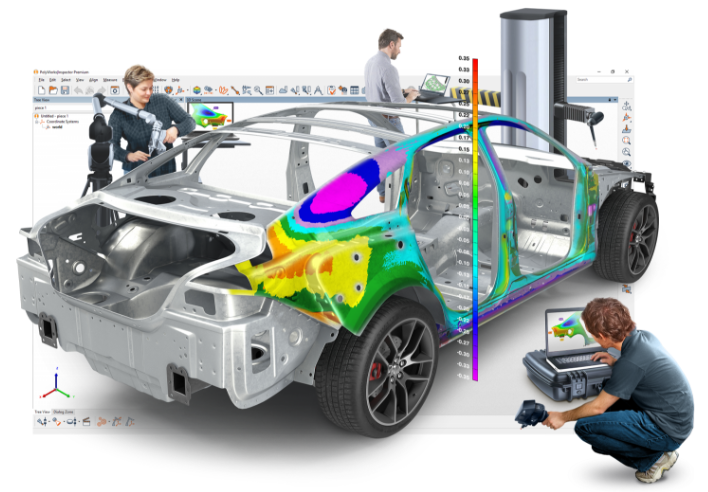

PolyWorks|InspectorTM is a universal 3D dimensional analysis and quality control software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using portable metrology devices and CNC CMMs.

Universal Software Platform

With just one software to master, dramatically reduce your operational costs by increasing measurement specialist competency, eliminating metrology silos, boosting employee mobility, and improving overall teamwork efficiency.

Interface with all 3D measurement devices thanks to a universal digitizing hub

|

Bring all relevant data under one roof through a universal data hub

|

Perform all inspection tasks with or without CAD data using a universal 3D metrology workflow

|

Deploy universal inspection projects playable on any 3D measurement device

|

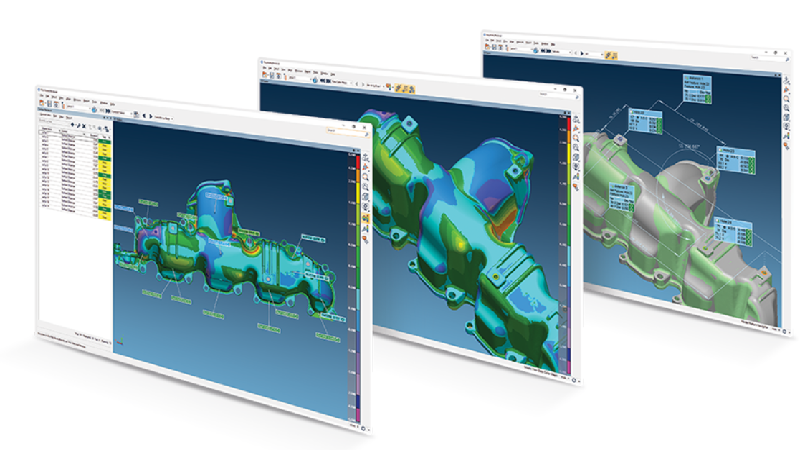

Complete Dimensional Analysis and Quality Control Toolbox

At the heart of PolyWorks|Inspector lies a powerful inspection engine with parametric data handling, , and extensive visual and audio feedback capabilities. It allows users to extract meaningful information from their measured 3D data, automate the inspection process when more than one piece is measured, and structure the presentation of measurement results to facilitate enterprisewide digital collaboration.

Always get the alignment right

|

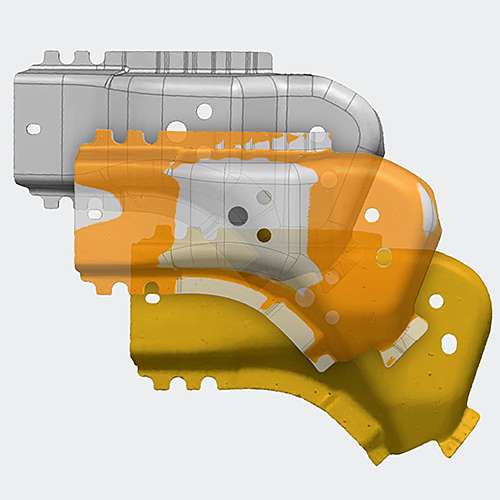

Surface and cross section best-fitBest-fit measured surfaces and cross-sections to their nominal definition, with the option of constraining in rotation, translation, or within a tolerance zone. |

Measurement object best-fitConstruct your alignment from features, datum targets, surface points, or edge points, and use weights and axial constraints to optimize the results. |

Multiple device position alignmentAlign your 3D measurement device while compensating for temperature changes, and use bundle adjustment to maximize the global accuracy. |

Measure all required dimensions

|

Universal data handlingExtract measured dimensions from point clouds, polygonal models, or probed points, and nominal dimensions from a CAD model or a measured part. |

Deviation analysis using color mapsObtain surface, boundary, cross-sectional, or thickness measured-to-nominal deviations, and analyze them through a color map display. |

Feature-based dimensioningMeasure a feature’s diameter, position, or orientation, or distances and angles between two features, in 2D or in 3D, and configure the dimensions’ display intuitively. |

Smart GD&TBenefit from a smart GD&T engine based on the latest ASME and ISO standards, with advanced DRF, material condition, datum modifier, and tolerance zone capabilities. |

Profile and Flush & Gap gaugingEvaluate advanced dimensions on fillets, design feature lines, and sheet metal part assemblies, such as radius, angle, bending, sharpness, flush, and gap. |

Airfoil gaugingExtract advanced features on fan, compressor, and turbine blades to control and analyze dimensions, such as edge radius, thickness, length, width, angle, and area. |

Automate quality control tasks

|

Multipiece data managementMeasure multiple pieces using different 3D measurement devices, and store them in a single project folder or an online using an optimal format that minimizes disk space usage. |

Play Inspection toolUse the powerful Play Inspection and Sequence Editor tools to automate measurement workflows by ordering and triggering operations.

|

Macro scriptingAdd macro scripts to your measurement workflows to apply proprietary techniques, provide special feedback, or interconnect to other systems.

|

Review inspection results efficiently

|

Control viewsOrganize projects containing hundreds of dimensional and GD&T controls into small and logical groups of controls, with individual controls tied to specific alignments and coordinate systems. |

Statistical Process Control (SPC)Assess the repeatability and predictability of your manufacturing processes with multipiece statistics automatically calculated for object dimensions and surface deviations. |

Measurement System AnalysisDesign and carry out repeatability and Gauge R&R studies and publish results in elegant, content-rich Excel templates using . |

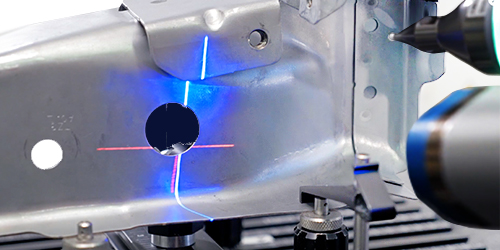

Market-leading Portable Metrology Platform

Renowned for the power and stability of its direct hardware interfaces, PolyWorks|Inspector offers an extensive set of guidance technologies that the world’s largest manufacturing OEMs trust to implement efficient, precise, and repeatable measurement processes for portable metrology devices.

Maximize the productivity of your scanning armsTens of thousands of portable arm operators worldwide enjoy the reliability and efficiency of our scanning and probing workflows every day. |

Leverage our disruptive laser tracker innovationsWe provide innovative laser-tracker-based scanning technologies that greatly accelerate the analysis and dimensional control of your large parts and tools. |

Scan large structures rapidly using spherical digitizingMinimize rework time when assembling large aerospace structures by scanning them using a spherical grid digitizer and simulating the assembly process beforehand. |

Tailor measurement methods to your processesIntegrate additional measurement devices or in-house proprietary measurement techniques by creating and embedding macro scripts within your measurement objects. |

Generate high-quality surface scansProduce great scanning results under all circumstances thanks to our unique real-time quality meshing technology that computes and displays quality metrics in real time.

|

Ensure sufficient scanned data for reliable feature extractionGet real-time feedback on scanned surface, curve, and circumference coverage with guidance graphics that indicate where an operator should capture additional scans.

|

Implement repeatable probing workflowsUse images, text, 3D graphics, and tolerances, on your computer screen or a mixed-reality display, to deploy guided probing inspection projects that improve operator efficiency and ensure measurement repeatability on the shop floor. |

Guide assembly building with real-time measurementsAccurately track part location during assembly using digital readouts simultaneously displaying real-time measured reflector positions from multiple laser trackers.

|

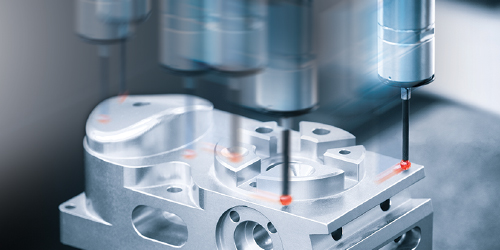

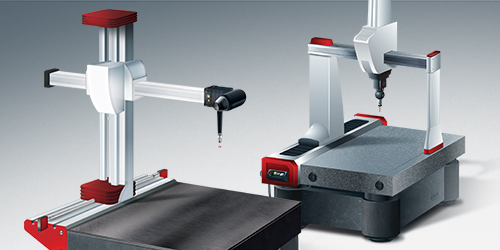

High-productivity CNC CMM Solution

PolyWorks|Inspector has reinvented the way inspection projects are set up and executed on CNC CMMs, within a flexible, user-friendly, and efficient CNC CMM operational paradigm, similar to the one we offer for portable metrology devices.

Reduce the complexity of your CMM programming tasksWe deliver shorter and easy-to-understand CNC CMM sequences, as our nominal features, dimensions, and reports are created and managed outside of the sequence editor. |

Accelerate the sequencing process while staying in controlSelect objects to be measured and let the sequence editor automatically find the proper tool orientations, the optimal measurement order, and collision-free measurement paths. |

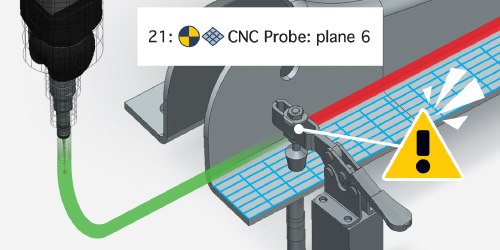

Fix sequencing mistakes intuitivelyOur intelligent sequence editor provides immediate feedback when illogical or incorrect operations are detected, and lets you repair detected mistakes in a single click.

|

Avoid potential collisions automaticallyWe offer powerful collision analysis and avoidance technologies that detect potential tool collisions in real time and automatically modify the toolpaths to prevent them.

|

Configure a CNC CMM sequence for any machine in your parkBuild your measurement sequence once for a specific CNC CMM configuration, then use our conversion tool to automatically adapt it to any CNC CMM brand or type. |

Protect your CNC CMM and its accessoriesAvoid costly damages by detecting, in real time, potential tool collisions with parts or fixtures prior to launching a CNC measurement operation online.

|

Add measurement objects to a sequence effortlesslyTo perform additional measurements, just create and select new measurement objects and let the sequence editor optimally insert them within your CNC CMM sequence. |

Complement your CNC CMM projects with portable metrology dataUse a portable laser scanner to measure the fixtures for collision analysis purposes, or a scanning arm to measure surfaces and features that can’t be reached by the CMM. |

Packages

Technical Specifications

Computer Requirements

Minimum Computer Requirements*

*These requirements are adequate if you are planning to use single-point probing devices and your CAD model file sizes are smaller than 50 MB.

|

Recommended Computer Requirements**

**This configuration covers a broad range of applications by offering the performance required when importing larger CAD models or laser scanning large parts with high resolution. If you have doubts about the best system configuration for your type of application, contact our technical support team. |

|

|