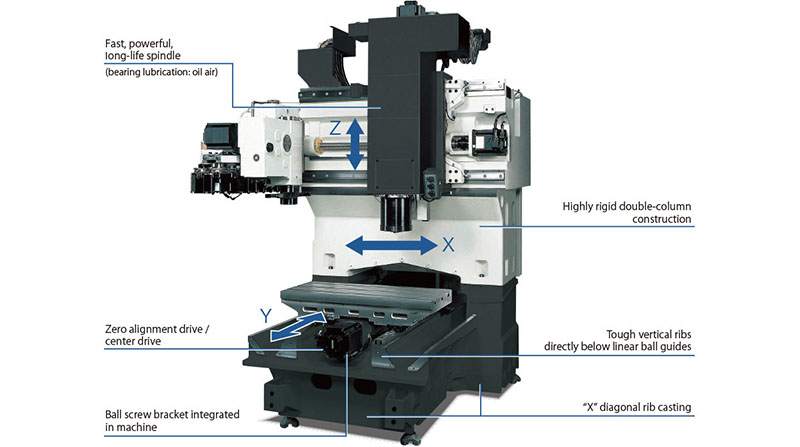

Highly rigid construction for productivity that exceeds expectations

- Rugged machine structure developed using 3D-CAD and FEM analysis

- Same rugged column structure as used in our proven column machining centers

- Bearing bracket of feeding axis integrated into the machine

Powerful spindles provide heavy-duty cutting with ease

Cutting capacities:

- 504cm3/min(face milling)

- 672cm3/min(end milling)

- 8,000min-1(No.40)/6,000min-1(No.50) high power spindle (Standard)

| Tool | Spindle min-1 |

Cutting m/min |

Feedrate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

| ø80 face mill 8 blades (cermet) | 895 | 225 | 2,600 | 56 | 2.5 | 364 |

| ø20 roughing end mill, 7 flutes (carbide) |

3,660 | 230 | 4,300 | 4 | 20 | 344 |

| ø50 insert drill | 1,000 | 157 | 150 | – | – | – |

| Tap M30P3.5 | 318 | 30 | 1,113 | – | – | 60% (Spindle load) |

(Workpiece material: S45C)

- 15,000min-1(No.40)wide-range spindle (Optional)

| Tool | Spindle min-1 |

Cutting m/min |

Feedrate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

| ø80 face mill 8 blades (cermet) | 895 | 225 | 3,000 | 56 | 3 | 504 |

| ø20 roughing end mill, 7 flutes (carbide) |

4,000 | 251 | 4,800 | 7 | 20 | 672 |

| ø63 insert drill | 720 | 142 | 108 | – | – | – |

| Tap M30P3.5 | 318 | 30 | 1,113 | – | – | 66% (Spindle load) |

(Workpiece material: S45C)

- 12,000min-1(No.50)wide-range spindle (Optional)

| Tool | Spindle min-1 |

Cutting m/min |

Feedrate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

| ø80 face mill 8 blades (cermet) | 895 | 225 | 3,000 | 56 | 3 | 504 |

| ø20 roughing end mill, 7 flutes (carbide) |

4,000 | 251 | 2,800 | 12 | 20 | 672 |

| ø63 insert drill | 909 | 180 | 137 | – | – | – |

| Tap M36P4 | 106 | 12 | 424 | – | – | – |

(Workpiece material: S45C)

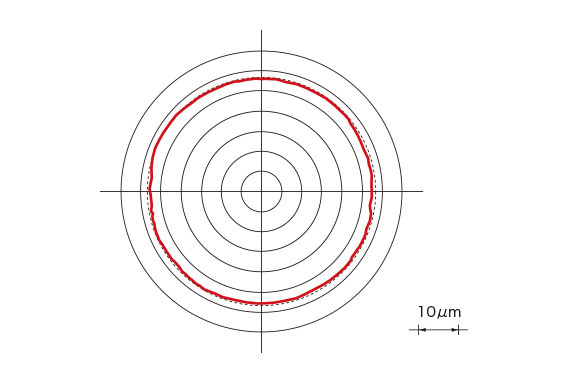

Parts machined with higher quality

High-accuracy machining

| ■ Flatness 3μm (actual data) ・Machine: MB-66VA ・Machined part: Plate (LCD) ・Material: A5052 ・Size: 560 × 600 × 60 mm ・Cycle time: 50 min |

■ Roundness 1.65μm (actual data) ・Machine: MB-56VA ・Machining dia: ø150 mm ・Material: Al ・Spindle speed: 8,000 min-1 ・Feedrate: 2,000mm/min |

|

|

Positioning accuracy

MB-46VA with AbsoScale; actual data (measurement method based on ISO 230-2)

| ■ The exactness of bi-directional positioning ・X-axis (travel 560 mm) 1.7μm ・Y-axis (travel 460 mm) 2.4μm ・Z-axis (travel 460 mm) 2.2μm |

■ Bi-directional repeatability ・X-axis (travel 560 mm) 1.0μm ・Y-axis (travel 460 mm) 1.3μm ・Z-axis (travel 460 mm) 1.0μm |

※The “actual data” referred to above represent examples of data obtained by using ISO 230-2 test methods done at Okuma factories, and they are not guaranteed values.

Thermo-Friendly Concept

The “Thermo-friendly” concept enables remarkable machining accuracy through original structural design and thermal deformation control technology. If frees you from troublesome dimensional compensation and warm-up. Exhibits excellent dimensional stability even during consecutive operation over long periods and environmental temperature change in the plant.

Machine Specifications:

| Item | MB-46VA <VAE> MB-46VB <VBE> |

MB-56VA MB-56VB |

MB-66VA MB-66VB |

||

| Travels | X-axis (ram saddle R/L) | mm (in.) | 560 <762> (22.05 <30.00>) |

1,050 (41.34) | 1,500(59.06) |

| Y-axis (table B/F) | mm (in.) | 460 (18.11) | 560 (22.05) | 660 (25.98) | |

| Z-axis (spindle U/D) | mm (in.) | 460 (18.11) | 660 (25.98) | ||

| Table top to spindle nose | mm (in.) | 150 to 610 (5.91 to 24.02) | 150 to 810 (5.91 × 31.89) | ||

| Table | Max work dimension | mm (in.) | 760 × 460 <1,000 × 460> (29.92 × 18.11 <39.37 × 18.11>) |

1,300 × 560 (51.18 × 22.05) |

1,530 × 660 (60.24 × 25.98) |

| Floor to table top | mm (in.) | 800(31.50) | 850(33.46) | ||

| Max load capacity | kg (lb) | 500 <700> (1,100 <1,540>) |

900(1,980) | 1,500 (3,300) |

|

| Spindle | Spindle speed | min-1 | 8,000 [15,000, 20,000, 25,000, 35,000] (*1) | ||

| 6,000 [12,000] | |||||

| Speed ranges | Infinintely variable | ||||

| Tapered bore | 7/24 taper No. 40 [HSK-A63 / HSK-F63] (*1) | ||||

| 7/24 taper No. 50 | |||||

| Bearing dia | mm (in.) | ø70 [ø70, ø70, ø60, ø60] (ø2.76 [ø2.76, ø2.76, ø2.37, ø2.37]) (*1) | |||

| ø90 [ø90] (ø3.54 [ø3.54]) | |||||

| Feedrate | Rapid traverse | m/min (ipm) | X-Y : 40 (1,575) Z : 32 (1,260) | ||

| Cutting feedrate | mm/min (ipm) | X-Y-Z : 32,000 (1,260) | |||

| Motors | Spindle | kW (hp) | 11/7.5 [22/18.5, 30/22, 15/11, 15] (15/10 [30/25, 40/30, 20/15, 20]) (*1) | ||

| 11/7.5 [26/18.5] (15/10 [35/25]) | |||||

| Feed axes | kW (hp) | X-Y-Z : 3.5 (4.7) | X-Y-Z : 4.6 (6.1) | ||

| ATC | Tool shank | MAS BT.40 [HSK] | |||

| MAS BT.50 | |||||

| Pull stud | MAS 2 [−] | ||||

| MAS 2 | |||||

| Tool capacity | tool | 20 [32, 48] 48-tool only for MB-46VAE, MB-56VA, MB-66VA | |||

| Max tool dia (w/adjacent tool) |

mm (in.) | ø90 (ø3.54) | |||

| ø100 (ø3.94) | |||||

| Max tool dia (w/o adjacent tool) |

mm (in.) | ø125 (ø4.92) | |||

| ø152 (ø5.98) | |||||

| Max tool length | mm (in.) | 300 (11.81) | 400 (15.75) | ||

| Max tool mass | kg (lb) | 8 (18) | 8 (18) | ||

| 12 (26) | 12 [15] (26 [33]) | ||||

| Max tool moment | N-m (ft-lbf) | 7.8 (5.7) (8 kg × 100 mm (17.6 lb × 3.94 in.)) | |||

| 15.3 (12 kg × 130 mm) (11.3 (26.4 lb × 5.12 in.)) |

15.3 [19.1] (12 [15] kg × 130 mm) (11.3 [14.1]) (26.4 [33] lb × 5.12 in.) |

||||

| Tool selection | Memory random | ||||

| Machine size | Height | mm (in.) | 2,746 (108.11) | 3,295 (129.72) | |

| Floor space | mm (in.) | 1,976 (2,026*2) <2,236> × 2,810 (78 (80) <88> × 111) |

2,546 × 3,123 (100 × 123) |

3,035 × 3,325 (119 × 131) |

|

| Weight | kg (lb) | 6,800 <7,100> (14,960 <15,620>) |

8,300 (18,260) | 11,200 (24,640) | |

| 7,000 <7,300> (15,400 <16,060>) |

8,500 (18,700) | 11,800 (25,960) | |||

[ ]: Optional

< >: E (extension type)

*1. 35,000 min-1 spindle (15 kW, HSK-F63) not available with MB-66VA

*2. MB-46VB