High-speed micro machining can be done on a normal machining center, eliminating the need of expensive high-speed machine.

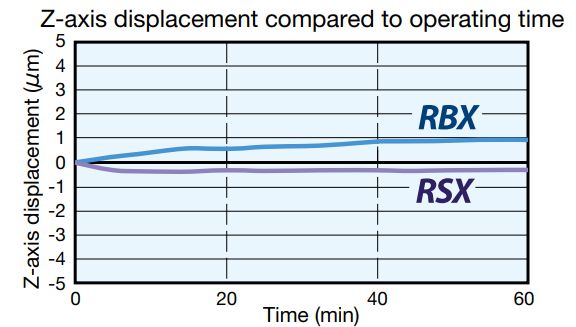

Extended tool life with minimal thermal displacement

High speed rotation of the machine spindle generates heat, causing spindle expansion and Z-axial displacement. This displacement results in dimension defects of precision molds or tool breakage in micro machining.

The Air Turbine Spindle utilizes air for both driving and cooling the spindle simultaneously, thus the Z-axis displacement is eliminated.

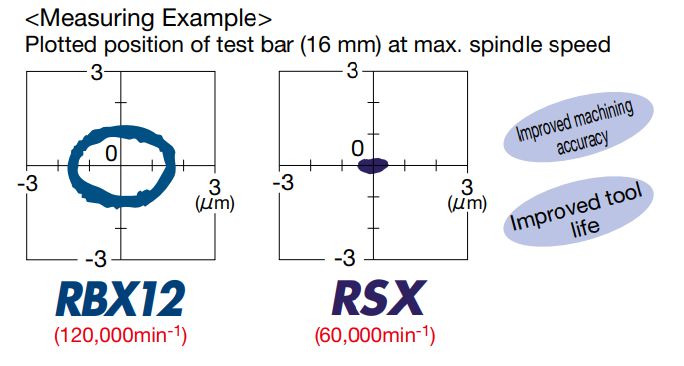

Outstanding dynamic runout accuracy

Most problems associated with micro-machining are caused by poor dynamic runout of a machine spindle. We have established a runout measuring system that can detect spindle movement during rotation at high speed and achieved the best dynamic runout accuracy.

Video:

Specification:

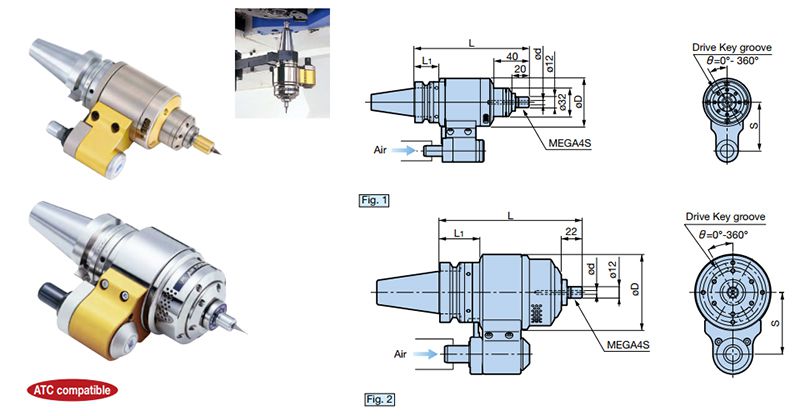

| Model | Fig. | Operating spindle speed (min-1) | Clamping diameter ød | Usable tool diameter | øD | L | L1 | Mega Nut | Collet Model | Weight (kg) |

| BBT30-RBX12C-4S-95 | 1 | 100,000 – 120,000 | 0.45 – 4.05 | ø0.6 or smaller | 32 | 95 | 70 | MGN4S-HG | NBC4S | 0.7 |

| BBT40-RBX5C-4S-150 | 2 | 40,000 – 50,000 | 0.45 – 4.05 | ø1.5 or smaller | 96 | 150 | – | MGN4S | NBC4S | 4.1 |

| BBT40-RBX7C-4S-150 | 60,000 – 80,000 | ø1.0 or smaller | 78 | – | 3.1 | |||||

| BBT40-RBX12C-4S-95 | 1 | 100,000 – 120,000 | ø0.6 or smaller | 32 | 95 | 65 | MGN4S-HG | 1.3 | ||

| BBT50-RBX5C-4S-160 | 2 | 40,000 – 50,000 | 0.45 – 4.05 | ø1.5 or smaller | 96 | 160 | – | MGN4S | NBC4S | 7.3 |

| BBT50-RBX7C-4S-160 | 60,000 – 80,000 | ø1.0 or smaller | 78 | – | 6.3 |

| Model | Fig. | Operating spindle speed (min-1) | Clamping diameter ød | Usable tool diameter | øD | L | L1 | S | Mega Nut | Collet Model | Weight (kg) |

| BBT30-RBX7-4S-152-55 | 2 | 60,000 – 80,000 | 0.45 – 4.05 | ø1.0mm or smaller | 80 | 152 | 28 | 55 | MGN4S-HG | NBC4S | 2.7 |

| BBT30-RBX12-4S-130-55 | 1 | 100,000 – 120,000 | ø0.6mm or smaller | 54 | 130 | MGN4S-HG | 1.7 | ||||

| BBT40-RBX5-4S-151-65 | 2 | 40,000 – 50,000 | 0.45 – 4.05 | ø1.5mm or smaller | 96 | 151 | 43 | 65 | MGN4S | NBC4S | 5.0 |

| BBT40-RBX7-4S-151-65 | 60,000 – 80,000 | ø1.0mm or smaller | 80 | 4.0 | |||||||

| BBT40-RBX12-4S-135-65 | 1 | 100,000 – 120,000 | ø0.6mm or smaller | 63 | 135 | – | MGN4S-HG | 3.0 | |||

| BBT50-RBX5-4S-166-80 | 2 | 0.45 – 4.05 | ø1.5 or smaller | 100 | 166 | 58 | 80 | MGN4S | NBC4S | 9.7 | |

| BBT50-RBX7-4S-166-80 | 60,000 – 80,000 | ø1.0 or smaller | 8.7 |

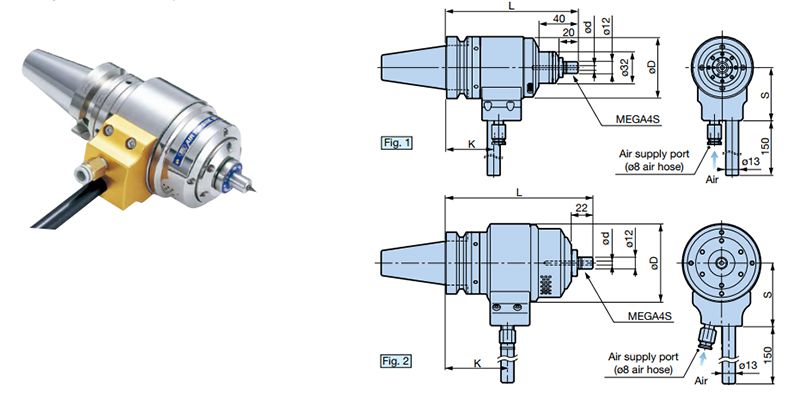

| Model | Fig. | Operating spindle speed (min-1) | Clamping diameter ød | Usable tool diameter | L | øD | K | S | Mega Nut | Collet Model | Weight (kg) |

| BBT30-RBX7-4S-152H | 2 | 60,000 – 80,000 | 0.45 – 4.05 | ø1.0mm or smaller | 152 | 80 | 64.5 | 65 | MGN4S | NBC4S | 2.7 |

| BBT30-RBX12-4S-130H | 1 | 100,000 – 120,000 | ø0.6mm or smaller | 130 | 54 | 46 | 50 | MGN4S-HG | 1.7 | ||

| BBT40-RBX5-4S-151H | 2 | 40,000 – 50,000 | 0.45 – 4.05 | ø1.5mm or smaller | 151 | 96 | 63 | 71 | MGN4S | NBC4S | 5.0 |

| BBT40-RBX7-4S-151H | 60,000 – 80,000 | ø1.0mm or smaller | 80 | 65 | 4.0 | ||||||

| BBT40-RBX12-4S-135H | 1 | 100,000 – 120,000 | ø0.6mm or smaller | 135 | 63 | 49 | 54 | MGN4S-HG | 2.7 | ||

| BBT50-RBX5-4S-166H | 2 | 40,000 – 50,000 | 0.45 – 4.05 | ø1.5mm or smaller | 166 | 100 | 78 | 80 | MGN4S | NBC4S | 9.7 |

| BBT50-RBX7-4S-166H | 60,000 – 80,000 | ø1.0mm or smaller | 8.7 |