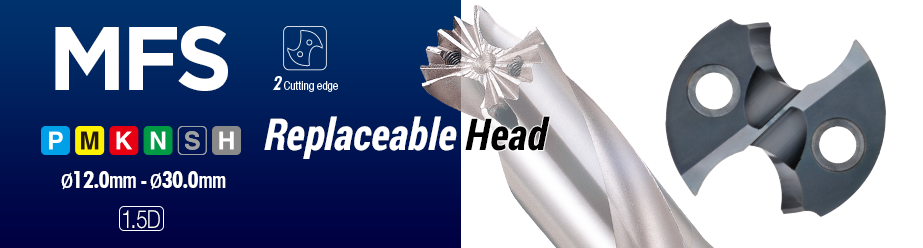

Replaceable type drill with exchangeable heads using an unique radial serration design, for high precision and strength

An exchangeable drill head provides a new cutting edge, higher productivity and cost efficiency with easy tool management.

Regrinding allowance of 1.5mm to 3mm makes further tool cost reductions possible.

Stable machining of mild steel, stainless steel, etc.

|

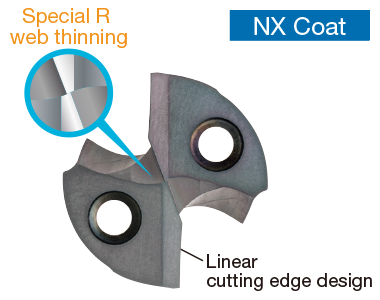

● Overwhelming cutting edge sharpness in mild steel and SUS machining Newly designed linear cutting edge and special R web thinning enables improved chip evacuation and stable machining ● Stable long tool life New grade improves fracture and adhesion resistance |

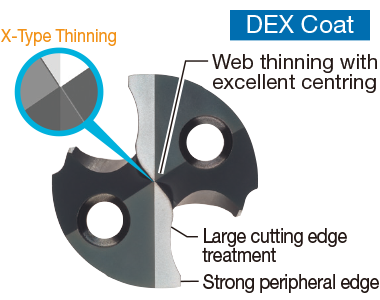

Suitable for high-efficiency drilling of general steel

|

● Excellent cutting edge strength Large edge treatment is used to reduce breakage of the cutting edge. ● Stable machined hole accuracy X Type thinning achieves excellent centring on entry and stable drilling. |

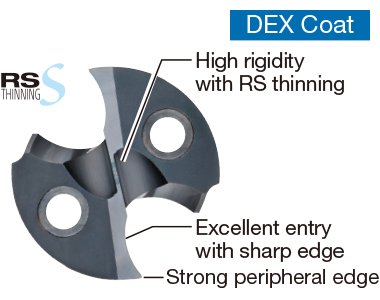

Ideal for drilling and burr control on non-flat surfaces

|

● Ideal for drilling and burr control on non-flat surfaces Can be used for high-efficiency spot facing, drilling on non-horizontal surfaces such as inclined and cylindrical surfaces, and interrupted drilling. Also reduces burrs at the hole exit. ● Improves machining stability Achieves high rigidity by employing RS THINNING, which ensures thick web. |

Optimized design for drilling rolled steel for welded structures (single or stacked plates)

|

① Gradual Arc Shape J-Flute Unique wide and smooth flute shape significantly improves chipcontrol and evacuation. ② Reduces peripheral edge chipping caused by flapping workpieces Robust Substrate and Reinforced Edge Treatment ③ Excellent fracture resistance + chip control Dedicated cutting edge design ④ Directs coolant to cutting edge evenduring MQL drilling Centre Oil Hole |