Flexible machining from all directions

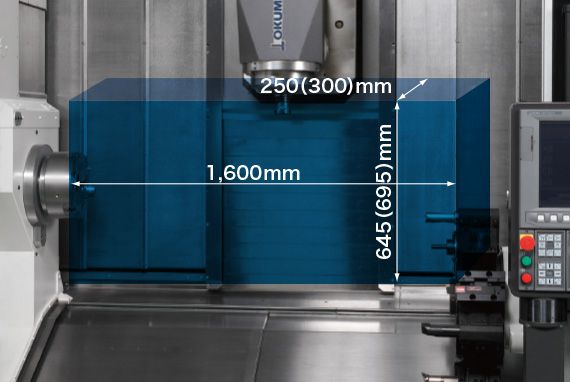

Tough cutting in entire Y-axis rangeWith the ideal, large work envelope for lots of milling of complex parts. The class best Y-axis travel is fully utilized with a highly rigid traveling column, for powerful cutting along the entire Y axis. |

Wide B-axis swing: 240°The wide 240-degree swing of the B axis spindle allows it to have equivalent machining areas for both the main and opposing spindle. With the NC-B axis, roller gears are used to achieve “0” backlash during B-axis drive, and highly accurate 5-axis machining. |

|

|

Superb C-axis positioning accuracy: 0.0001°control

As an option*, a highly accurate C-axis function is used for both the main and opposing spindles. This will support end-users requiring very accurate machining of component shapes that are quite complex.

Moreover, heavy-duty milling, with a solid retention mechanism, makes possible applications that require both high accuracy and high efficiency.

* Standard in certain markets.

Maximum milling or turning performance

Achieving highly efficient cutting of difficult-to-machine materials

|

End milling 604cm3/min(S45C) ø20-mm end mill 7-flute Cutting Speed: 192m/min Cutting depth: 6.5×20mm Feed rate: 1.52mm/rev (MULTUS U3000) |

OD Turning 5.0mm2(S45C) Cutting Speed: 150m/min Cutting depth: 8mm Feed rate: 0.625mm/rev (MULTUS U4000 / MULTUS U5000 ø160 spindle) |

An array of extended specs to match user workpiece applications

Selections designed to match user workpiece applications

29 diverse variations in all

An assortment of variations are available for every possible requirement. You can choose the right solution that matches your application needs.

Achieves process-intensive machining beyond the framework of multitasking machines

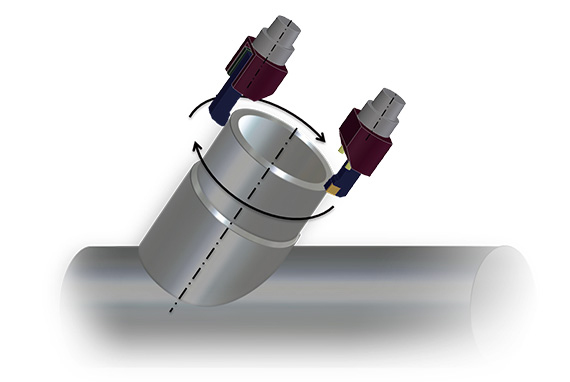

Sloped axis turning

Turn-Cut

Turn-Cut is an original Okuma technology that enables turning on a milling spindle. The circular turning of the feed shaft and the spindle indexing angle are simultaneously controlled so that the tool edge is always facing the center of the milling spindle circular turning.

Sloped axis turning can be done by sloping the B axis. Moreover, machining of any diameter can be done with a single tool. Inside and outside diameter machining that is larger than the maximum tool diameter can be done. In setting cutting conditions, the Turn-Cut Guide (Optional) advises the best turning speed when the diameter and roundness of the machining area are designated.

|

|

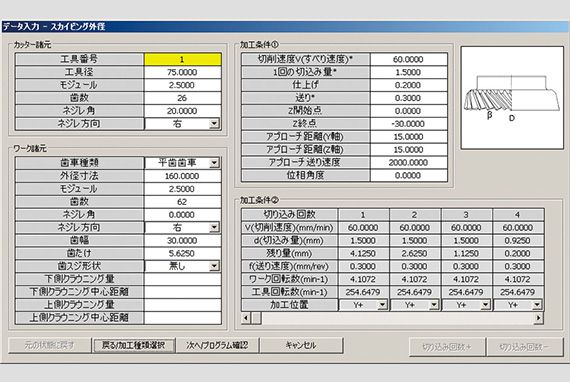

High accuracy gear cutting with a multitasking machine

Gear Machining Package (Optional)

Gear cutting that previously required complex programming can now be done with ease. With easy programming, simply input the tool type, gear data, and cutting conditions to achieve highly accurate machining, reducing programming time to about one-tenth that of manual input. Process-intensive machining is achieved, including the gear cutting that used to be done on expensive special-purpose machines.

(MULTUS U3000)

|

|

|

| Skiving (OD/ID splines) | Hobbing | Input screen |

VIDEO MULTUS U Series:

VIDEO MULTUS U5000:

Machine Specifications:

| Item | MULTUS U3000 | |||||||||

| 1SC | 1SW | 2SC | 2SW | |||||||

| 1000 | 1500 | 1000 | 1500 | 1000 | 1500 | 1000 | 1500 | |||

| Capacity | Swing over saddle | mm (in.) | ø650 (25.59) | Upper: ø650 (25.59), Lower: ø320 (12.60) | ||||||

| Distance between centers | mm (in.) | 1,000 (39.37) | 1,500 (59.06) | 1,000 (39.37) | 1,500 (59.06) | 1,000 (39.37) | 1,500 (59.06) | 1,000 (39.37) | 1,500 (59.06) | |

| Max machining dia | mm (in.) | ø650 (25.59) | Upper: ø650 (25.59)*1, Lower: ø320 (12.60) | |||||||

| Max machining length | mm (in.) | 1,000 (39.37) | 1,500 (59.06) | 1,000 (39.37) | 1,500 (59.06) | 1,000 (39.37) | 1,500 (59.06) | 1,000 (39.37) | 1,500 (59.06) | |

| Travels | X axis | mm (in.) | 645 (25.39) | Upper: 645 (25.39), Lower: 235 (9.25) | ||||||

| Z axis | Upper: mm (in.) | 1,100 (43.31) | 1,600 (62.99) | 1,100 (43.31) | 1,600 (62.99) | 1,100 (43.31) | 1,600 (62.99) | 1,100 (43.31) | 1,600 (62.99) | |

| Lower: mm (in.) | – | 961 (37.83) | 1,461 (57.52) | 1,100 (43.31) | 1,584 (62.36) | |||||

| Y axis | mm (in.) | 250 (9.84) (±125 (4.92)) | ||||||||

| W axis | mm (in.) | – | 1,325 (52.17) | 1,594 (62.76) | – | 1,100 (43.31) | 1,584 (62.36) | |||

| B-axis / indexing angle | degree | -30 to 210 (min controlled angle 0.001) | ||||||||

| C-axis / indexing angle | degree | 360 (min controlled angle 0.0001) | ||||||||

| Spindle | Speed | min-1 | 50 to 5,000 | |||||||

| Speed ranges | 2 auto ranges (2-speed motor coil switching) | |||||||||

| Nose shape | JIS A2-6 | |||||||||

| Taper bore | mm (in.) | ø80 (3.15) | ||||||||

| Bearing dia | mm (in.) | ø120 (4.72) | ||||||||

| Opposing spindle* | Speed | min-1 | − | 50 to 5,000 | − | 38 to 5,000 | ||||

| Speed ranges | − | 2 auto ranges (2-speed motor coil switching) | − | 2 auto ranges (2-speed motor coil switching) | ||||||

| Nose shape | − | JIS A2-6 | − | JIS A2-6 | ||||||

| Taper bore | mm (in.) | − | ø80 (3.15) | − | ø62 (2.44) | |||||

| Bearing dia | mm (in.) | − | ø120 (4.72) | − | ø100 (3.94) | |||||

| Turret (tool spindle) |

Type | H1 | Upper: H1, Lower: V12 | |||||||

| No. of tools | L / M: 1 | Upper: L / M: 1, Lower: 12 | ||||||||

| Tool shank dimensions | mm (in.) | □25(1 × 1) | ||||||||

| ID tool shank diameter | mm (in.) | ø40 (1-1/2) | ||||||||

| Milling tool spindle | min-1 | Upper: 50 to 12,000 | ||||||||

| Milling tool spindle speed ranges | Upper: 2 auto ranges (2-speed motor coil switching) | |||||||||

| Feed rates | X, Z, Y axes | Upper: m/min | X:50, Z:50, Y:40 | |||||||

| lower: m/min | − | X: 25, Z: 40 | ||||||||

| W-axis | m/min | 20 (tailstock) |

12 (tailstock) |

30 | 20 (tailstock) |

12 (tailstock) |

30 | |||

| C, B axis | min-1 | C: 200, B: 30 | ||||||||

| Tailstock | Tapered bore | MT No.5 (revolving center) |

– | MT No.5 (revolving center) |

– | |||||

| Travel | mm (in.) | 1,186 (46.69) |

1,594 (62.76) |

– | 961 (37.83) |

1,359.5 (53.52) |

– | |||

| ATC | Tool shank | HSK-A63 | ||||||||

| No. of tools | tools | 40 | ||||||||

| Max tool dia | mm (in.) | ø90 (3.54) (w/o adjacent tools: ø130 (5.12)) | ||||||||

| Max tool length | mm (in.) | 400 (15.75) (from gauge line) | ||||||||

| Max tool mass | kg (lb) | 10 (22) | ||||||||

| Motor | Main spindle motor | kW (hp) | 22/15 (30/20) (30 min/cont) | |||||||

| Opposing spindle motor | kW (hp) | − | 22/15 (30/20) (30 min/cont) |

− | 22/15 (30/20) (20 min/cont) |

|||||

| Milling tool spindle motor | kW(hp) | 25/19 (33/25) (3 min/cont) | ||||||||

| X-, Z-, Y-, B axis motors | kW(hp) | X: 5.2, Z: 4.6, Y: 3.5, B: 3.0 (X: 6.9, Z: 6.1, Y: 4.7, B: 4.0) |

XA: 5.2, ZA: 4.6, Y: 3.5, B: 3.0 (XA: 6.9, ZA: 6.1, Y: 4.7, B: 4.0) XB: 3.5, ZB: 3.5 (XB: 4.7, ZB: 4.7) (DBC 1,000)/ 4.6 (6.1) (DBC 1,500) |

|||||||

| W-axis motor | kW(hp) | 2.8 (3.7) (tailstock) | 3.5 (4.7) | 4.6 (6.1) | 2.8 (3.7) (tailstock) | 3.5 (4.7) | 4.6 (6.1) | |||

| Coolant motor (50Hz/60Hz) | kW(hp) | 0.25/0.25 (0.33/0.33)×1 , 0.55/0.75(0.73/1.0)×3 | ||||||||

| Machine size | Height | mm (in.) | 2,955 (116.34) | 3,030 (119.29) | ||||||

| Floor space W × D (tank included) |

mm × mm (in.) | DBC 1,000: 4,925 × 2,995 (193.90 × 117.91) DBC 1,500: 5,425 × 2,995 (213.58 × 117.91) |

DBC 1,000: 4,925 × 3,018 (193.90 × 118.82) DBC 1,500: 5,425 × 3,082 (213.58 × 121.34) |

|||||||

| Mass | kg(lb) | DBC 1,000: 15,500 (34,100) DBC 1,500: 16,500 (36,300) |

DBC 1,000: 16,500 (36,300) DBC 1,500: 17,500 (38,500) |

|||||||

| CNC | OSP-P300SA | |||||||||

*1.ø320 (swing over lower turret) during shaft work and when machining with opposing spindles.

*The opposing spindle capacity and working range near the opposing spindle differ with 1SW and 2SW specifications.

| Item | MULTUS U4000 | |||||||||

| 1SC | 1SW | 2SC | 2SW | |||||||

| 1500 | 2000 | 1500 | 2000 | 1500 | 2000 | 1500 | 2000 | |||

| Capacity | Swing over saddle | mm (in.) | ø650 (25.59) | Upper: ø650 (25.59), Lower: ø320 (12.60) | ||||||

| Distance between centers | mm (in.) | 1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

|

| Max machining dia | mm (in.) | ø650 (25.59) | Upper: ø650 (25.59)*1, Lower: ø320 (12.60) | |||||||

| Max machining length | mm (in.) | 1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

|

| Travels | X axis | mm (in.) | 695 (27.36) | Upper: 695 (27.36), Lower: 235 (9.25) | ||||||

| Z axis | upper: mm (in.) | 1,600 (62.99) |

2,100 (82.68) |

1,600 (62.99) |

2,100 (82.68) |

1,600 (62.99) |

2,100 (82.68) |

1,600 (62.99) |

2,100 (82.68) |

|

| lower: mm (in.) | – | 1,461 (57.52) |

1,961 (77.20) |

1,524*2 (60.00) |

2,045*3 (80.51) |

|||||

| Y axis | mm (in.) | 300 (11.81) (±150 (5.91)) | ||||||||

| W axis | mm (in.) | – | 1,554 (61.18) |

2,054 (80.87) |

– | 1,524*2 (60.00) |

2,024*3 (79.69) |

|||

| B-axis / indexing angle | degree | −30 to +210 (min controlled angle 0.001) | ||||||||

| C-axis / indexing angle | degree | 360 (min controlled angle 0.0001) | ||||||||

| Spindle | Speed | min-1 | 45 to 4,200 | |||||||

| Speed ranges | 2 auto ranges (2-speed motor coil switching) | |||||||||

| Nose shape | JIS A2-8 | |||||||||

| Taper bore | mm (in.) | ø91 (3.58) | ||||||||

| Bearing dia | mm (in.) | ø140 (5.51) | ||||||||

| Opposing spindle* | Speed | min-1 | − | 45 to 4,200 | − | 38 to 3,800 | ||||

| Speed ranges | − | 2 auto ranges (2-speed motor coil switching) |

− | 2 auto ranges (2-speed motor coil switching) |

||||||

| Nose shape | − | JIS A2-8 | − | JIS A2-8 | ||||||

| Taper bore | mm (in.) | − | ø91 (3.58) | − | ø80 (3.15) | |||||

| Bearing dia | mm (in.) | − | ø140 (5.51) | − | ø120 (4.72) | |||||

| Turret (tool spindle) |

Type | H1 | H1, Lower: V12 | Upper: H1, Lower: V12 | ||||||

| No. of tools | L / M: 1 | Upper: L / M: 1, Lower: 12 | ||||||||

| Tool shank dimensions | mm (in.) | □25 (1 × 1) | ||||||||

| ID tool shank diameter | mm (in.) | ø40 (1-1/2) | ||||||||

| Milling tool spindle | min-1 | Upper: 50 to 12,000 | ||||||||

| Milling tool spindle speed ranges | Upper: 2 auto ranges (2-speed motor coil switching) | |||||||||

| Feed rates | X, Z, Y axes | upper: m/min | X: 50, Z: 50,Y: 40 | X: 50, Z: 40,Y: 40 | X: 50, Z: 50,Y: 40 | X: 50, Z: 40,Y: 40 | X: 50, Z: 50,Y: 40 | X: 50, Z: 40,Y: 40 | X: 50, Z: 50,Y: 40 | X: 50, Z: 40,Y: 40 |

| lower: m/min | − | X: 25, Z: 40 | X: 25, Z: 30 | X: 25, Z: 40 | X: 25, Z: 30 | |||||

| W-axis | m/min | 12 (tailstock) |

30 | 20 | 12 (tailstock) |

30 | 20 | |||

| C, B axes | min-1 | C: 200, B: 30 | ||||||||

| Tailstock | Tapered bore | MT No. 5 (revolving center) |

– | MT No. 5 (revolving center) |

– | |||||

| Travel | mm (in.) | 1,594 (62.76) |

2,094 (82.44) |

– | 1,359.5 (53.52) |

1,961 (77.20) |

– | |||

| ATC | Tool shank | HSK-A63 | ||||||||

| No. of tools | tools | 40 | ||||||||

| Max tool dia | mm (in.) | ø90 (3.54) (w/o adjacent tools: ø130 (5.12)) | ||||||||

| Max tool length | mm (in.) | 400 (15.75) (from gauge line) | ||||||||

| Max tool mass | kg (lb) | 10 (22) | ||||||||

| Motor | Main spindle motor | kW (hp) | 22/15 (30/20) (30 min/cont) | |||||||

| Opposing spindle motor | kW (hp) | − | 22/15 (30/20) (30 min/cont) |

− | 22/15 (30/20) (20 min/cont) |

|||||

| Milling tool spindle motor | kW (hp) | 25/19 (33/25) (3 min/cont) | ||||||||

| X-, Z-, Y-, B-axis motors | kW (hp) | X: 5.2, Z: 4.6 (X: 6.9, Z: 6.1) (DBC 1,500)/ 5.2 (6.9) (DBC 2,000),Y: 3.5 (4.7), B: 3.0 (4.0) |

XA: 5.2, ZA: 4.6 (DBC 1,500), /5.2 (DBC 2,000) (XA: 6.9, ZA: 6.1 (DBC 1,500), /6.9 (DBC 2,000)) XB: 3.5, ZB: 4.6, Y: 3.5, B: 3.0 (XB: 4.7, ZB: 6.1, Y: 4.7, B: 4.0) |

|||||||

| W-axis motor | kW (hp) | 2.8 (3.7) (tailstock) | 4.6 (6.1) | 2.8 (3.7) (tailstock) | 4.6 (6.1) | |||||

| Coolant motor (50Hz/60Hz) | kW (hp) | 0.25/0.25 (0.33/0.33)×1, 0.55/0.75 (0.73/1.0)×3 | ||||||||

| Machine size | Height | mm (in.) | 2,955 (116.34) | 3,030 (119.29) | ||||||

| Floor space W × D (tank included) |

mm × mm (in.) | DBC 1,500: 5,425 × 2,995 (213.58 × 117.91) DBC 2,000: 6,175 × 2,995 (243.11 × 117.91) |

DBC 1,500: 5,425 × 3,082 (213.58 × 121.34) DBC 2,000: 6,175 × 3,082 (243.11 × 121.34) |

|||||||

| Mass | kg (lb) | DBC 1,500: 17,000 (37,400) DBC 2,000: 19,000 (41,800) |

DBC 1,500: 18,000 (39,600) DBC 2,000: 20,000 (44,000) |

|||||||

| CNC | OSP-P300SA | |||||||||

*1.ø320 (swing over lower turret) during shaft work and when machining with opposing spindles.

*2.In the main Big-Bore spindle, it will be 1,500.

*3.In the main Big-Bore spindle, it will be 2,000.

*The opposing spindle capacity and working range near the opposing spindle differ with 1SW and 2SW specifications.

| Item | MULTUS U5000 | |||||||||

| 1SC | 1SW | 2SC | 2SW | |||||||

| 1500 | 2000 | 1500 | 2000 | 1500 | 2000 | 1500 | 2000 | |||

| Capacity | Swing over saddle | mm (in.) | ø650 (25.59) | Upper: ø650 (25.59), Lower: ø320 (12.60) | ||||||

| Distance between centers | mm (in.) | 1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

|

| Max machining dia | mm (in.) | ø650 (25.59) | Upper: ø650 (25.59)*1, Lower: ø320 (12.60) | |||||||

| Max machining length | mm (in.) | 1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

1,500 (59.06) |

2,000 (78.74) |

|

| Travels | X axis | mm (in.) | 695 (27.36) | Upper: 695 (27.36), Lower: 235 (9.25) | ||||||

| Z axis | upper:mm (in.) | 1,600 (62.99) |

2,100 (82.68) |

1,600 (62.99) |

2,100 (82.68) |

1,600 (62.99) |

2,100 (82.68) |

1,600 (62.99) |

2,100 (82.68) |

|

| lower:mm (in.) | – | 1,461 (57.52) |

1,961 (77.20) |

1,524 (60.00) |

2,024 (79.69) |

|||||

| Y axis | mm (in.) | 300 (11.81) (±150 (5.91)) | ||||||||

| W axis | mm (in.) | – | 1,554 (61.18) |

2,054 (80.87) |

– | 1,500 (59.06) |

2,000 (78.74) |

|||

| B-axis / indexing angle | degree | -30 to +210 (min controlled angle 0.001) | ||||||||

| C-axis / indexing angle | degree | 360 (min controlled angle 0.0001) | ||||||||

| Spindle | Speed | min-1 | 30 to 3,000 | |||||||

| Speed ranges | 2 auto ranges (2-speed motor coil switching) | |||||||||

| Nose shape | JIS A2-11 | |||||||||

| Taper bore | mm (in.) | ø112 (4.41) | ||||||||

| Bearing dia | mm (in.) | ø160 (6.30) | ||||||||

| Opposing spindle* | Speed | min-1 | − | 30 to 3,000 | − | 38 to 3,800 | ||||

| Speed ranges | − | 2 auto ranges (2-speed motor coil switching) |

− | 2 auto ranges (2-speed motor coil switching) |

||||||

| Nose shape | − | JIS A2-11 | − | JIS A2-8 | ||||||

| Taper bore | mm (in.) | − | ø112 (4.41) | − | ø80 (3.15) | |||||

| Bearing dia | mm (in.) | − | ø160 (6.30) | − | ø120 (4.72) | |||||

| Turret (tool spindle) |

Type | H1 | H1, Lower: V12 | |||||||

| No. of tools | L / M: 1 | Upper: L / M: 1, Lower: 12 | ||||||||

| Tool shank dimensions | mm (in.) | □25 (1 × 1) | ||||||||

| ID tool shank diameter | mm (in.) | ø40 (1-1/2) | ||||||||

| Milling tool spindle | min-1 | Upper: 50 to 12,000 | ||||||||

| Milling tool spindle speed ranges | Upper: 2 auto ranges (2-speed motor coil switching) | |||||||||

| Feed rates | X, Z, Y axes | upper: m/min | X: 50, Z: 50, Y: 40 | X: 50, Z: 40, Y: 40 | X: 50, Z: 50, Y: 40 | X: 50, Z: 40, Y: 40 | X: 50, Z: 50, Y: 40 | X: 50, Z: 40, Y: 40 | X: 50, Z: 50, Y: 40 | X: 50, Z: 40, Y: 40 |

| lower: m/min | − | X: 25, Z: 40 | X: 25, Z: 30 | X: 25, Z: 40 | X: 25, Z: 30 | |||||

| W-axis | m/min | 8 (tailstock) | 30 | 20 | 8 (tailstock) | 30 | 20 | |||

| C, B axes | min-1 | C: 200, B: 30 | ||||||||

| Tailstock | Tapered bore | MT No. 5 (Built-in) | – | MT No. 5 (Built-in) | – | |||||

| Travel | mm (in.) | 1,554 (61.18) |

2,054 (80.87) |

– | 1,359.5 (53.52) |

1,961 (77.20) |

– | |||

| ATC | Tool shank | HSK-A63 | ||||||||

| No. of tools | tools | 40 | ||||||||

| Max tool dia | mm (in.) | ø90 (3.54) (w/o adjacent tools: ø130 (5.12)) | ||||||||

| Max tool length | mm (in.) | 400 (15.75) (from gauge line) | ||||||||

| Max tool mass | kg (lb) | 10 (22) | ||||||||

| Motor | Main spindle motor | kW (hp) | 37/30 (49/40) (30 min/cont) | |||||||

| Opposing spindle motor | kW (hp) | − | 32/22 (42/30) (20 min/cont) |

− | 22/15/11 (30/20/15) (20 min/cont) |

|||||

| Milling tool spindle motor | kW (hp) | 25/19 (33/25) (3 min/cont) | ||||||||

| X-, Z-, Y-, B-axis motors | kW (hp) | X: 5.2, Z: 4.6 (DBC 1,500) /5.2 (DBC 2,000) (X: 6.9, Z: 6.1 (DBC 1,500) /6.9 (DBC 2,000)) Y: 3.5, B: 3.0 (Y: 4.7, B: 4.0) |

XA: 5.2, ZA: 4.6 (DBC 1,500), /5.2 (DBC 2,000) (XA: 6.9, ZA: 6.1 (DBC 1,500), /6.9 (DBC 2,000)) XB: 3.5, ZB: 4.6, Y: 3.5, B: 3.0 (XB: 4.7, ZB: 6.1, Y: 4.7, B: 4.0) |

|||||||

| W-axis motor | kW (hp) | 2.8 (3.7) (tailstock) | 4.6 (6.1) | 2.8 (3.7) (tailstock) | 4.6 (6.1) | |||||

| Coolant motor (50Hz/60Hz) | kW(hp) | 0.25/0.25 (0.33/0.33) × 1, 0.55/0.75 (0.73/1.0) ×3 | ||||||||

| Machine size | Height | mm (in.) | 2,955 (116.34) | 3,030 (119.29) | ||||||

| Floor space W × D (tank included) |

mm × mm (in.) | DBC 1,500: 5,530 × 2,995 (217.72 × 117.91) DBC 2,000: 6,280 × 2,995 (247.24 × 117.91) |

DBC 1,500: 5,530 × 3,082 (217.72 × 121.34) DBC 2,000: 6,280 × 3,082 (247.24 × 121.34) |

|||||||

| Mass | kg (lb) | DBC 1,500: 17,300 (38,060) DBC 2,000: 19,300 (42,460) |

DBC 1,500: 18,300 (40,260) DBC 2,000: 20,300 (44,660) |

|||||||

| CNC | OSP-P300SA | |||||||||

*1.ø320 (swing over lower turret) during shaft work and when machining with opposing spindles.

*The opposing spindle capacity and working range near the opposing spindle differ with 1SW and 2SW specifications.