Machine structure for high speed feed and high rigidity

- Highly rigid 3-point supported bed

Easy installation thanks to bed that does not twist.

Supporting stable, high accuracy over a long period. - Ball screw bracket

The ball screw brackets at both ends of the X-Y-Z axes are reinforced and combined for highly accurate drive and positioning. - Ball screw cooling

X-Z axis ball screw cooling and Y-axis motor bracket cooling are standard. Assuring stable accuracy during high rates of operation. - Indexing table, pallet

Indexing table uses curvic coupling for high-accuracy indexing.

Std: 1 degree

Opt: NC 0.001°

Pallet seating surface uses a taper cone system for high accuracy positioning and high durability.

High-speed operation that reduces non-cutting time

- Rapid traverse: 60 m/min (X-Y-Z axes)

- Rapid acceleration: 0.7G (maximum)

- Tool change: 2.0 sec (T-T) / 4.4 sec (C-C)

- Table indexing:

2.0 sec (MA-600HⅡ 1 degree indexing 90 degrees)

2.5 sec (MA-600HⅡ 0.001 degree indexing 90 degrees) - APC time: 12 sec (MA-600HⅡ)

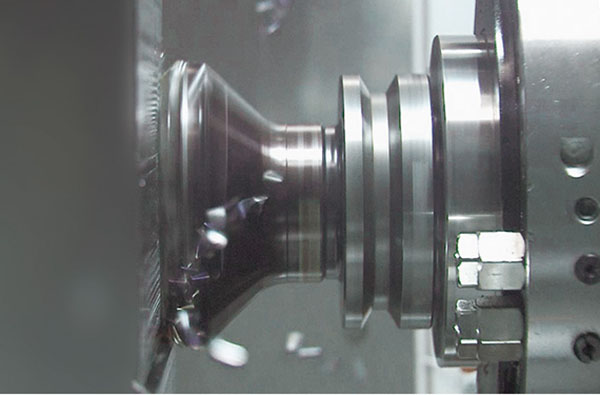

Ideal performance levels from a variety of spindles for a wide range of applications

Highly efficient production with high machining capacity

Machining capacity:

901cm3/min (MA-500HⅡ actual data*1)

Standard spindle: 6,000 min-1 ø100 face mill Material: S45C

| Tool | Spindle speed min-1 |

Cutting m/min |

Feedrate mm/min |

Cut width mm |

Cut depth mm |

Chips cm3/min |

| ø100 face mill 10 blades (carbide) | 955 | 300 | 3,220 | 70 | 4 | 901 |

| ø50 porcupine cutter (carbide) | 1,146 | 180 | 500 | 25 | 50 | 625 |

| ø63 insert drill (carbide) | 606 | 120 | 121 | – | – | – |

| M42 P4.5 tap | 91 | 12 | 409.5 | – | – | 81%* |

* Spindle load

802cm3/min (MA-600HⅡ actual data*1)

Wide-range spindle: 12,000 min-1 ø100 face mill Material: S45C

| Tool | Spindle speed min-1 |

Cutting m/min |

Feedrate mm/min |

Cut width mm |

Cut depth mm |

Chips cm3/min |

| ø100 face mill 10 blades (carbide) | 955 | 300 | 2,865 | 70 | 4 | 802 |

| ø50 porcupine cutter (carbide) | 1,146 | 180 | 400 | 25 | 50 | 500 |

| ø63 insert drill (carbide) | 606 | 120 | 91 | – | – | – |

| M42 P4.5 tap | 91 | 12 | 409.5 | – | – | – |

1,081cm3/min (MA-600HⅡ actual data*1)

Super-heavy spindle: 6,000 min-1 (Optional) ø200 face mill Material: S45C

| Tool | Spindle speed min-1 |

Cutting m/min |

Feedrate mm/min |

Cut width mm |

Cut depth mm |

Chips cm3/min |

| ø200 face mill 10 blades (cermet) | 330 | 207 | 1,404 | 140 | 5.5 | 1,081 |

*1 Dữ liệu được đăng ở trên là giá trị hiệu suất thực tế. Do sự khác biệt về thông số kỹ thuật, công cụ, điều kiện xử lý, v.v., dữ liệu thu được có thể khác với dữ liệu đã đăng.

Outstanding dimensional stability with long-run machining of large workpieces

Manageable Deformation—Accurately Controlled

Thermo-Friendly Concept

Dimensional changes of less than 8μm over time in a wide machining range (actual data with room temperature change of 8°C [TAS-C applicable])

In addition to maintaining high dimensional accuracy when room temperature changes, Okuma’s Thermo-Friendly Concept provides high dimensional accuracy during machine startup and machining restart.

To stabilize thermal deformation, warming-up time is shortened and the burden of dimensional correction during machining restart is reduced.

Machine Specifications:

| Item | Unit | MA-500HⅡ | MA-600HⅡ | |||

| No. 50 | No. 40*1 | No. 50 | No. 40*1 | |||

| Travels | X-axis travel (column left/right) |

mm (in.) | 700 (27.56) | 1,000 (39.37) | ||

| Y-axis travel (spindle up/down) |

mm (in.) | 900 (35.43) | ||||

| Z-axis travel (table front/back) |

mm (in.) | 780 (30.71) | 1,000 (39.37) | |||

| Spindle center to pallet top | mm (in.) | 50 to 950 (1.97 to 37.40) | ||||

| Spindle nose to pallet center | mm (in.) | 70 to 850 (2.76 to 33.46) | 70 to 1,070 (2.76 to 42.13) | |||

| Pallet | Work area | mm (in.) | 500 × 500 (19.69 × 19.69) | 630 × 630 (24.80 × 24.80) | ||

| Max load capacity | kg (lb) | 800 [1,000] (1,760 [2,200]) | 1,200 [1,400] (2,640 [3,080]) | |||

| Indexing angle | deg | 1 [0.001] | ||||

| Max workpiece dimensions | mm (in.) | ø800 × 1,000 (ø31.50 × 39.37) | ø1,000 × 1,000 (ø39.37 × 39.37) | |||

| Spindle | Spindle speed | min-1 | 50 to 6,000[50 to 6,000(Super-heavyspindle), 50 to12,000] | 50 to 15,000, 50 to 20,000 | 50 to 6,000[50 to 6,000,(Super-heavyspindle), 50 to12,000, 20,000] | 50 to 15,000, 50 to 20,000 |

| Tapered bore | 7/24 taper No. 50[HSK-A100] | 7/24 taper No. 40, HSK-A63*2 | 7/24 taper No. 50[HSK-A100]*3 | 7/24 taper No. 40, HSK-A63*2 | ||

| Bearing dia | mm (in.) | ø100 (ø3.94) | ø70 (ø2.76) | ø100 (ø3.94) | ø70 (ø2.76) | |

| Feedrate | Rapid traverse | m/min (ipm) | X-Y-Z: 60 (2,362) | |||

| Cutting feed | mm/min (ipm) | X-Y-Z: 1 to 60,000 (0.04 to 2,362) | ||||

| Motors | Spindle (10 min/cont) *4 | kW (hp) | 30/22[45/37*4, 37/26](40/30[60/50, 50/35]) | 26/18.5, 30/22(35/25, 40/30) | 30/22 [45/37*4,37/26, 55/50*5](40/30 [60/50,50/35, 75/66]) | 26/18.5, 30/22(35/25, 40/30) |

| Feed axis motors | kW (hp) | X: 4.6 (6.13), Y: 4.6 (6.13) × 2, Z: 4.6 (6.13) | X: 4.6 (6.13), Y: 4.6 (6.13) × 2, Z: 5.2 (6.93) | |||

| Table indexing | kW (hp) | 3.5 (4.67) | ||||

| ATC | Tool shank | MAS403 BT50[HSK-A100] | MAS 403 BT40, HSK-A63*2 | MAS403 BT50[HSK-A100]*3 | MAS 403 BT40, HSK-A63*2 | |

| Pull stud | MAS-2 [–] | |||||

| Magazine capacity | tools | 40 [60, 81, 111, 141, 171, 195, 225, 255, 285, 320, 400] | ||||

| Max tool dia (w/ adjacent) *6 |

mm (in.) | ø140 (5.51) | ø100 (3.94) | ø140 (5.51) | ø100 (3.94) | |

| Max tool dia (w/o adjacent) *6 |

mm (in.) | ø240 (9.45) | ø150 (5.91) | ø240 (9.45)*7 | ø150 (5.91) | |

| Max tool length | mm (in.) | 450 (17.72) | 450 (17.72) | 450 [600] (17.72 [23.62]) | 450 (17.72) | |

| Max tool weight | kg (lb) | 25 (55) | 10 (22) | 25 (55) | 10 (22) | |

| Tool selection | Memory random (Fixed with 81 or more tools) | |||||

| Machine size | Height | mm (in.) | 3,174 (124.96) | |||

| Floor space; width x depth | mm (in.) | 3,110 × 5,971 (122.44 × 235.08) | 3,410 × 6,495 (134.25 × 255.71) | |||

| Weight | kg (lb) | 21,500 (47,300) | 24,500 (53,900) | |||

| Controller | OSP-P300MA | |||||

[ ]: Optional

*1. No. 40 spindle is optional.

*2. 20,000 min-1 with HSK-A63 only

*3. 20,000 min-1 with HSK-A100 only

*4. Super-heavy spindle motor rating is 20 min/cont (for heavy-duty cutting)

*5. 20,000 min-1 spindle motor rating is 30 min/cont

*6. Values differ with a matrix magazine. Please inquire.

*7. With MA-600HⅡ 20,000 min-1, the maximum tool diameter is limited depending on the spindle speed used.