THE FEATURES OF CNC-SERIES EDM:

- THE HIGHLY RIGID, FINE-GRAINED CAST IRON MACHINE BASE, COLUMN, TABLE, AND MEEHANITE CAST IRON COMPONENTS, PROVIDE FOR STABILITY & LONG SERVICE LIFE.

- THREE AXES EQUIPPED P-CLASS LINEAR GUIDES (MADE IN JAPAN, GERMANY OR SWITZERLAND) ON SLIDEWAYS.

(CNC-430,580,650,2010) AND LINEAR SCALES FEED BACK DC SERVO SYSTEM FOR PRECISE ORBITAL POSITIONING. - X,Y,Z AXES ADOPT PRECISION CLASS BALLSCREWS AND DOUBLE UNTS ON WIDE SADDLE, SUPPORT THE TABLE MOVEMENT FOR EASY & ACCURACY POSITIONING.

- THE PC BASED CONTROLLER ADAPTED DIALOG PROGRAM EDITOR AND COLOR 15″ LCD-TFT. SIMPLE & CLEAR TOUCH PANEL. ALL DIGITAL EDM PARAMETER (S-CODE) FOR EASY TO UNDERSTAND & OPERATION.

- AUTOMATIC POSITIONING, ORBITING MOTION & SIDE SPARKING FUNCTION. AND AUTOMATIC EDGE, CENTER POINT & DEEPEST POINT FINDING; REFERENCE POINT SEARCHING & MULTI-COORDINATE MEMORY FUNCTION.

- NEW CNC CONTROLLER EQUIPPED VARIOUS MOTION MODE FOR SETTING(E-CODE) AS : CIRCLE, SQUARE, SECTOR, TAPER, INNER & OUTER SPHERE RADIATION, 45 DEGREE, AND THE 3-AXES LINAR, 2-AXES ARC, 3-AXES SPATIAL AND 4-AXES CONTOURING (OPTIONAL C-AXIS.) OFF-SET MOVEMENT.

- AUTO EDITING FUNCTION : JUST INPUT THAT E-CODE (MOTION MODE) & P-CODE (PROGRAMING MODE) & EDM DEPTH, OTHER MACHINING CONDITIONS WILL BE AUTO PRESET FROM THE SAVE DATA BANK, THEN MACHINE AUTOMATICALLY OPERATE FROM ROUGH TO FINE FINISH CIRCLE.

- NEW FUZZY LOGIC FOR ARCING CONTROL, AND FUZZY SERVO VOLTAGE CONTROL. WHEN THE DISCHARGING IS UNSTEADY, EDM PARAMENTERS WILL BE ADJUSTED BY THE CONTROLLER, THE ELECTRODE WILL BE JUMP BACK & UP AND PULSE-OFF WHEN ARCING.

- NEW CIS COLOR, WITH NEW METAL SHIELD COVER ON MACHINE WHICH CORRESPOND WITH CE SAFETY STANDARD 89/392EEC & 93/68/EEC.

- AUTOMATIC ELECTRODE CHANGER-ATC & C-AXIS OPTION AVAILABLE.

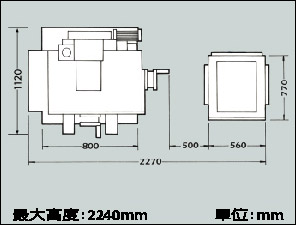

– CNC-250:

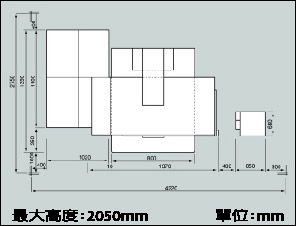

– CNC-430:

– CNC-460:

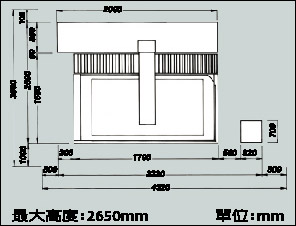

– CNC-580:

– CNC-650:

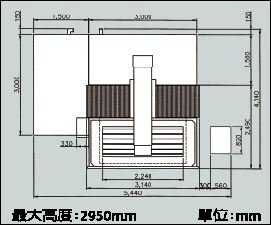

– CNC-2010:

MACHINE UNIT:

| SERIES NO. \ SPECIFIC. | CNC-250 | CNC-430 | CNC-460 |

| Work tank (WxDxH) inner size (WxDxH) mm/inch | 750x500x340 (29.5×19.7×13.4) |

1,090x600x370 (42.9×23.6×14.6) |

1,400x800x500 (55.1×31.5×19.7) |

| Work table size (XxY) mm/inch | 600×300 (23.6×11.8) | 650×350 (25.6×13.8) | 900×600 (35.4×23.6) |

| Work table travel (XxY) mm/inch | 300×200 (11.8×7.9) | 400×300 (15.7×11.8) | 600×500 (23.6×17.7) |

| Work head travel (W-axis) mm/inch | 200 (7.9) | 270 (10.6) | – |

| Ram servo travel (Z-axis) mm/inch | 180 (7.1) | 200 (7.9) | 300 (11.8) |

| Minimum/Max. distant between The table surface and electrode plate. mm/inch | 0~380(0~14.9) | 40~510(1.6~20.0)-STANDARD 270~570(10.6~22.4)-OPTIONAL |

450~750(17.7~29.5) |

| Max. electrode weight kgs/lbs | 50 (110) | 120 (264) | 200 (440) |

| Max. work piece weight kgs/lbs | 300 (660) | 400 (880) | 1,800 (3,960) |

| External dimension (WxDxH) mm/inch | 1,200×1,200×2,240 (47.2×47.2×86.6) |

1,210×1,400×2,040 (47.6×55.1×80.3) |

1,700×2,000×2,450 (66.9×78.8×96.5) |

| Packing dimension (WxDxH) mm/inch | 1,245×1,215×2,220 (49×47.8×87.4) |

1,515×1,320,2,230 (59.7x52x87.8) |

2,170×1,760×2,560 (85.4×69.3×100.8) |

| Net weight kgs/lbs | 1,050(2310)) | 1,800(3,960) | 2,800(6,160) |

| SERIES NO. \ SPECIFIC. | CNC-580 | CNC-650 | CNC-2010 |

| Work tank(WxDxH) inner size (WxDxH) mm/inch | 1,700×1,050×700 (66.9×41.3×27.6) |

2,150×1,150×700 (84.7×45.3×27.6) |

2,900×1,500×700 (114.2×59.1×27.6) |

| Work table size (XxY) mm/inch | 1,100×700 (43.3×27.6) | 1,400×900 (55.1×35.4) | 2,240×1,050 (88.2×41.3) |

| Work table travel (XxY) mm/inch | 1,100×600 (39.4×23.6) | 1,200×700 (47.3×27.6) | 2,000×1,000 (78.7×39.4) |

| Work head travel (W-axis) mm/inch | – | – | – |

| Ram servo travel (Z-axis) mm/inch | 450 (17.7) | 450 (17.7) | 550(21.7) |

| Minimum/Max. distant between The table surface and electrode plate. mm/inch | 520~970(20.5~38.2) | 560~1,100(22.1~43.3) | 600~1,150(23.6~45.3) |

| Max. electrode weight kgs/lbs | 400 (880) | 400 (880) | 500 (1,100) |

| Max. work piece weight kgs/lbs | 3,000 (6,600) | 4,000 (8,800) | 9,000 (19,800) |

| External dimension (WxDxH) mm/inch | 2,500×1,900×2,880 (98.4×74.8×113.4) |

2,500×2,500×3,040 (98.4×98.4×119.7) |

3,000×2,400×3,150 (118.14×94.5×124) |

| Packing dimension (WxDxH) mm/inch | 2,320×2,280×3,190 (94.4×89.8×125.6) |

2,340×2,300×2,500 (92.2×90.6×98.5) |

DEPEND ON REQUIRED |

| Net weight kgs/lbs | 5,400 (11,880) | 6,300 (13,200) | 13,000 (28,600) |