新型 CNC EDM 控制器及機台特點介紹:

- 提供100組以上檔案儲存,可以儲存100個不同模具、客戶編號之能力。

- 使用對話式程式設計,中文或英文操作畫面,公/英制切換,除自動定位、定孔加工外;並提供各種擴孔搖動模式:放射狀、圓形、方形,向量式直線、錐度、45 擴孔、內外圓球形模式加工。

- 具自動尋中心、基準點、快速尋邊、自動尋原點、多點座標記憶、中心測位自動補償等功能,可做三軸直線、兩軸圓弧、三軸螺旋、補間運動及圓形加工。

- 具40組加工程式檔(P-CODE)及多種三軸自動定位、擴孔功能(E-CODE)。輸入E-CODE,P-CODE及加工深度後,電腦自動編輯粗加工至細加工之程式檔案,粗→中→細→極細一次完成。

- 具電極消耗補償、Z 軸靠邊補償、各軸偏移值補償及歸零點移動,及設歸零點功能。

- 符合CE規範具防火、積碳偵測、液面警告裝置。並有退模、單節執行、空跑(DRY RUN),加跳躍執行功能。

- 機械原點自動歸零功能:加工中途停電時,電腦會自動找尋機械原點。

- X,Y 軸皆使用C5精密級滾珠導桿(460,550,580,650,2010三軸)雙螺帽並加寬之鞍底座,使工作台滑動順暢安穩。

- Z 軸皆採用德國製或日本製P級線性滑軌(LINEAR GUIDERS),(430,460,580,650,2010三軸)。

並使用光學尺(電子尺)回饋伺服定位系統,軌跡運動(ORBITAL CUTTING)時更加精準。 - 全新機台為全罩式鈑金及全新外觀顏色設計,及符合CE安全規範之電源箱及15″LCD液晶螢幕(顯示屏)。

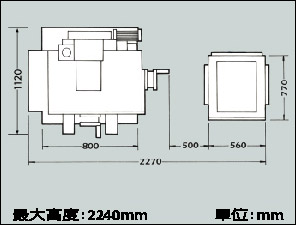

– CNC-250:

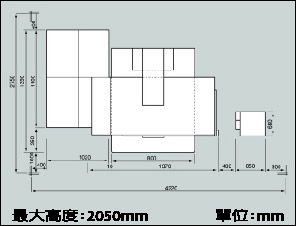

– CNC-430:

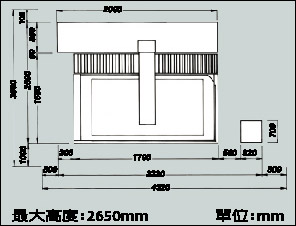

– CNC-460:

– CNC-580:

– CNC-650:

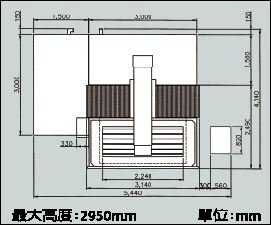

– CNC-2010:

機械尺寸:

| SERIES NO. \ SPECIFIC. | CNC-250 | CNC-430 | CNC-460 |

| Work tank (WxDxH) inner size (WxDxH) mm/inch | 750x500x340 (29.5×19.7×13.4) |

1,090x600x370 (42.9×23.6×14.6) |

1,400x800x500 (55.1×31.5×19.7) |

| Work table size (XxY) mm/inch | 600×300 (23.6×11.8) | 650×350 (25.6×13.8) | 900×600 (35.4×23.6) |

| Work table travel (XxY) mm/inch | 300×200 (11.8×7.9) | 400×300 (15.7×11.8) | 600×500 (23.6×17.7) |

| Work head travel (W-axis) mm/inch | 200 (7.9) | 270 (10.6) | – |

| Ram servo travel (Z-axis) mm/inch | 180 (7.1) | 200 (7.9) | 300 (11.8) |

| Minimum/Max. distant between The table surface and electrode plate. mm/inch | 0~380(0~14.9) | 40~510(1.6~20.0)-STANDARD 270~570(10.6~22.4)-OPTIONAL |

450~750(17.7~29.5) |

| Max. electrode weight kgs/lbs | 50 (110) | 120 (264) | 200 (440) |

| Max. work piece weight kgs/lbs | 300 (660) | 400 (880) | 1,800 (3,960) |

| External dimension (WxDxH) mm/inch | 1,200×1,200×2,240 (47.2×47.2×86.6) |

1,210×1,400×2,040 (47.6×55.1×80.3) |

1,700×2,000×2,450 (66.9×78.8×96.5) |

| Packing dimension (WxDxH) mm/inch | 1,245×1,215×2,220 (49×47.8×87.4) |

1,515×1,320,2,230 (59.7x52x87.8) |

2,170×1,760×2,560 (85.4×69.3×100.8) |

| Net weight kgs/lbs | 1,050(2310)) | 1,800(3,960) | 2,800(6,160) |

| SERIES NO. \ SPECIFIC. | CNC-580 | CNC-650 | CNC-2010 |

| Work tank(WxDxH) inner size (WxDxH) mm/inch | 1,700×1,050×700 (66.9×41.3×27.6) |

2,150×1,150×700 (84.7×45.3×27.6) |

2,900×1,500×700 (114.2×59.1×27.6) |

| Work table size (XxY) mm/inch | 1,100×700 (43.3×27.6) | 1,400×900 (55.1×35.4) | 2,240×1,050 (88.2×41.3) |

| Work table travel (XxY) mm/inch | 1,100×600 (39.4×23.6) | 1,200×700 (47.3×27.6) | 2,000×1,000 (78.7×39.4) |

| Work head travel (W-axis) mm/inch | – | – | – |

| Ram servo travel (Z-axis) mm/inch | 450 (17.7) | 450 (17.7) | 550(21.7) |

| Minimum/Max. distant between The table surface and electrode plate. mm/inch | 520~970(20.5~38.2) | 560~1,100(22.1~43.3) | 600~1,150(23.6~45.3) |

| Max. electrode weight kgs/lbs | 400 (880) | 400 (880) | 500 (1,100) |

| Max. work piece weight kgs/lbs | 3,000 (6,600) | 4,000 (8,800) | 9,000 (19,800) |

| External dimension (WxDxH) mm/inch | 2,500×1,900×2,880 (98.4×74.8×113.4) |

2,500×2,500×3,040 (98.4×98.4×119.7) |

3,000×2,400×3,150 (118.14×94.5×124) |

| Packing dimension (WxDxH) mm/inch | 2,320×2,280×3,190 (94.4×89.8×125.6) |

2,340×2,300×2,500 (92.2×90.6×98.5) |

DEPEND ON REQUIRED |

| Net weight kgs/lbs | 5,400 (11,880) | 6,300 (13,200) | 13,000 (28,600) |