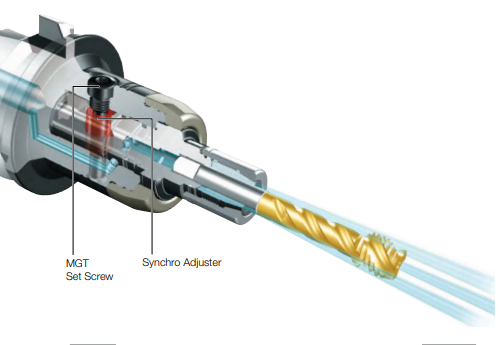

Tool holder for rigid tapping MEGA SYNCHRO Tapping Holder

Unique new mechanism built into compensate for synchronization errors

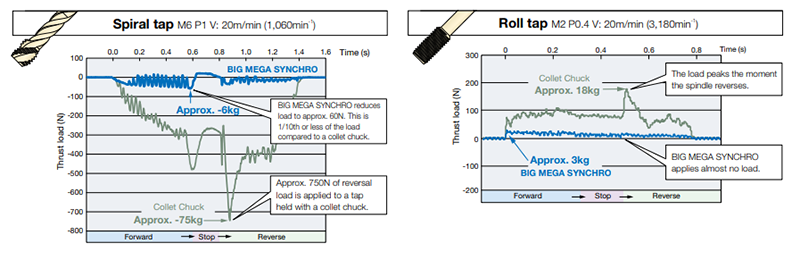

Improves thread quality and tap life by reducing thrust loads caused by synchronization errors up to 90%.

Reduces thrust load on both the tap and workpiece.

Due to feed misalignment occurring when the rotation is changed from forward to reverse, or tolerance to the tap pitch, 100% synchronization is hardly ever achieved. BIG MEGA SYNCHRO minimizes the thrust load to both the tap and workpiece to improve thread quality and tap life.

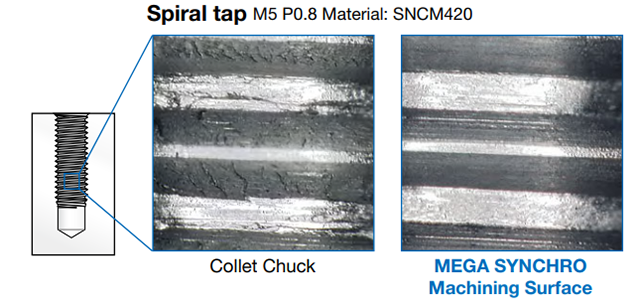

Comparison of surface finish

Tapping of difficult-to-cut materials with collet chuck tends to cause a compressed burr on the thread surface. BIG MEGA SYNCHRO compensates for synchronization errors and minimizes cutting load. Fine surface finish of threads is achieved.

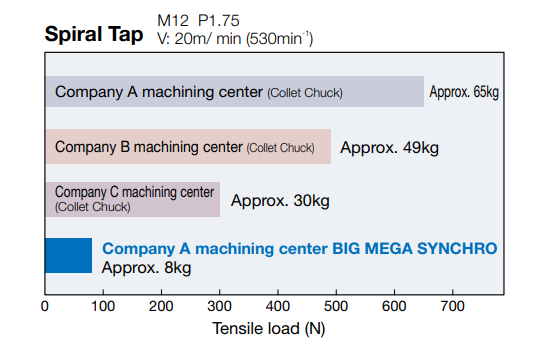

Difference in loads depending on machining centers

The movement of the machine differs even at the same rpm, creating a completely different load. Even with maximum load Company A machining centers, the use of BIG MEGA SYNCHRO drastically reduces the load.

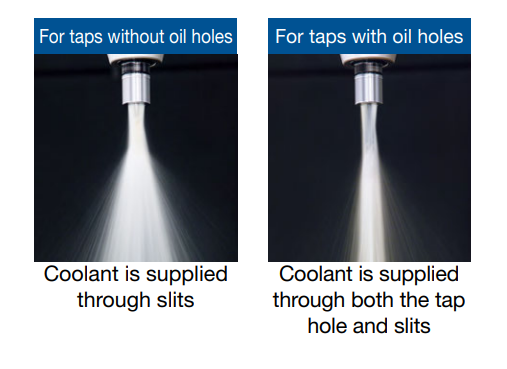

Center through cooling available as standard

Coolant is supplied both through the tool and to the tool periphery simultaneously, even for taps with oil holes.

VIDEO:

Abundant lineup from small to large diameter tapping

Lineup of types from small to large diameters

|

|

Small Diameter Tap MGT3 PAT

|

Large Diameter Tap MGT36 PAT

|

|

|

AUTO TAPPER B TYPE / R TYPE

|

AUTO TAPPER E TYPE

|

|

|

CK SYNCHRONIZED TAP HOLDER STC TYPE

|

DRILL TAPPER

|