實現高速進給和高剛性的機床結構

- 高剛性3點支撐床身

床身無扭曲,安裝簡便。

可長期維持高精度。 - 滾珠絲槓支架

X、Y、Z軸滾珠絲槓兩端的支架,經強化一體化適應高精度驅動和定位。 - 滾珠絲槓冷卻

標准採用X、Z軸滾珠絲槓冷卻、Y軸電機座冷卻。

確保高運轉率下的精度穩定。 - 工作台分度、托盤APC

通過齒牙盤進行分度實現工作台的高精度分度。- 標準:1度分度

- 特殊規格:NC 0.001度分度

APC採用圓錐銷定位,實現高精度定位和高耐久性。

高速動作減少非切削時間

- 快速進給速度:60m/min(X、Y、Z軸)

- 快速進給加速度:0.7G(最大)

- 刀具更換時間:2.0秒(T-T)/ 4.4秒(C-C)

- 工作台分度時間:2.0秒(MA-600HⅡ 1度分度 90度)/ 2.5秒(MA-600HⅡ 0.001度分度 90度)

- APC時間:12秒(MA-600HⅡ

以適應廣泛加工需求的主軸產品陣容實現高性價比

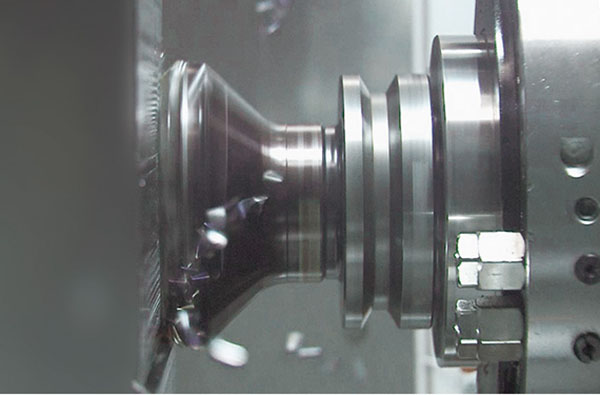

以高加工能力進行高效率生產

加工能力:

901cm3/min(MA-500HⅡ 實測值)

標準主軸 6,000min-1 ø100面銑刀 被切削材料∶S45C

| Tool | Spindle speed min-1 |

Cutting m/min |

Feedrate mm/min |

Cut width mm |

Cut depth mm |

Chips cm3/min |

| ø100 face mill 10 blades (carbide) | 955 | 300 | 3,220 | 70 | 4 | 901 |

| ø50 porcupine cutter (carbide) | 1,146 | 180 | 500 | 25 | 50 | 625 |

| ø63 insert drill (carbide) | 606 | 120 | 121 | – | – | – |

| M42 P4.5 tap | 91 | 12 | 409.5 | – | – | 81%* |

* Spindle load

802cm3/min(MA-600HⅡ 實測值)

廣域主軸 12,000min-1(特殊規格) ø100面銑刀 被切削材料∶S45C

| Tool | Spindle speed min-1 |

Cutting m/min |

Feedrate mm/min |

Cut width mm |

Cut depth mm |

Chips cm3/min |

| ø100 face mill 10 blades (carbide) | 955 | 300 | 2,865 | 70 | 4 | 802 |

| ø50 porcupine cutter (carbide) | 1,146 | 180 | 400 | 25 | 50 | 500 |

| ø63 insert drill (carbide) | 606 | 120 | 91 | – | – | – |

| M42 P4.5 tap | 91 | 12 | 409.5 | – | – | – |

1,081cm3/min(MA-600HⅡ 實測值)

大扭矩主軸 6,000min-1(特殊規格) ø200面銑刀 被切削材料∶S45C

| Tool | Spindle speed min-1 |

Cutting m/min |

Feedrate mm/min |

Cut width mm |

Cut depth mm |

Chips cm3/min |

| ø200 face mill 10 blades (cermet) | 330 | 207 | 1,404 | 140 | 5.5 | 1,081 |

※登載的數據為實績值,由於規格、刀具、加工條件等的不同,所得數據可能與登載的數據不同。

大型工件的長時間加工也可實現出眾的尺寸穩定性

準確控制規則的熱位移

Thermo-Friendly Concept

廣泛加工領域中實現經時加工尺寸變化 8μm 以下(室溫變化8℃<TAS-C適用時>實測值)

不僅實現了在室溫變化時保持尺寸的高穩定性,而且也實現了在機械起動時或再次開始加工時的尺寸的高穩定性。

縮短為使熱位移穩定下來的暖機運轉時間,以減輕再次開始加工時的尺寸修正負擔。

機床規格:

| Item | Unit | MA-500HⅡ | MA-600HⅡ | |||

| No. 50 | No. 40*1 | No. 50 | No. 40*1 | |||

| Travels | X-axis travel (column left/right) |

mm (in.) | 700 (27.56) | 1,000 (39.37) | ||

| Y-axis travel (spindle up/down) |

mm (in.) | 900 (35.43) | ||||

| Z-axis travel (table front/back) |

mm (in.) | 780 (30.71) | 1,000 (39.37) | |||

| Spindle center to pallet top | mm (in.) | 50 to 950 (1.97 to 37.40) | ||||

| Spindle nose to pallet center | mm (in.) | 70 to 850 (2.76 to 33.46) | 70 to 1,070 (2.76 to 42.13) | |||

| Pallet | Work area | mm (in.) | 500 × 500 (19.69 × 19.69) | 630 × 630 (24.80 × 24.80) | ||

| Max load capacity | kg (lb) | 800 [1,000] (1,760 [2,200]) | 1,200 [1,400] (2,640 [3,080]) | |||

| Indexing angle | deg | 1 [0.001] | ||||

| Max workpiece dimensions | mm (in.) | ø800 × 1,000 (ø31.50 × 39.37) | ø1,000 × 1,000 (ø39.37 × 39.37) | |||

| Spindle | Spindle speed | min-1 | 50 to 6,000[50 to 6,000(Super-heavyspindle), 50 to12,000] | 50 to 15,000, 50 to 20,000 | 50 to 6,000[50 to 6,000,(Super-heavyspindle), 50 to12,000, 20,000] | 50 to 15,000, 50 to 20,000 |

| Tapered bore | 7/24 taper No. 50[HSK-A100] | 7/24 taper No. 40, HSK-A63*2 | 7/24 taper No. 50[HSK-A100]*3 | 7/24 taper No. 40, HSK-A63*2 | ||

| Bearing dia | mm (in.) | ø100 (ø3.94) | ø70 (ø2.76) | ø100 (ø3.94) | ø70 (ø2.76) | |

| Feedrate | Rapid traverse | m/min (ipm) | X-Y-Z: 60 (2,362) | |||

| Cutting feed | mm/min (ipm) | X-Y-Z: 1 to 60,000 (0.04 to 2,362) | ||||

| Motors | Spindle (10 min/cont) *4 | kW (hp) | 30/22[45/37*4, 37/26](40/30[60/50, 50/35]) | 26/18.5, 30/22(35/25, 40/30) | 30/22 [45/37*4,37/26, 55/50*5](40/30 [60/50,50/35, 75/66]) | 26/18.5, 30/22(35/25, 40/30) |

| Feed axis motors | kW (hp) | X: 4.6 (6.13), Y: 4.6 (6.13) × 2, Z: 4.6 (6.13) | X: 4.6 (6.13), Y: 4.6 (6.13) × 2, Z: 5.2 (6.93) | |||

| Table indexing | kW (hp) | 3.5 (4.67) | ||||

| ATC | Tool shank | MAS403 BT50[HSK-A100] | MAS 403 BT40, HSK-A63*2 | MAS403 BT50[HSK-A100]*3 | MAS 403 BT40, HSK-A63*2 | |

| Pull stud | MAS-2 [–] | |||||

| Magazine capacity | tools | 40 [60, 81, 111, 141, 171, 195, 225, 255, 285, 320, 400] | ||||

| Max tool dia (w/ adjacent) *6 |

mm (in.) | ø140 (5.51) | ø100 (3.94) | ø140 (5.51) | ø100 (3.94) | |

| Max tool dia (w/o adjacent) *6 |

mm (in.) | ø240 (9.45) | ø150 (5.91) | ø240 (9.45)*7 | ø150 (5.91) | |

| Max tool length | mm (in.) | 450 (17.72) | 450 (17.72) | 450 [600] (17.72 [23.62]) | 450 (17.72) | |

| Max tool weight | kg (lb) | 25 (55) | 10 (22) | 25 (55) | 10 (22) | |

| Tool selection | Memory random (Fixed with 81 or more tools) | |||||

| Machine size | Height | mm (in.) | 3,174 (124.96) | |||

| Floor space; width x depth | mm (in.) | 3,110 × 5,971 (122.44 × 235.08) | 3,410 × 6,495 (134.25 × 255.71) | |||

| Weight | kg (lb) | 21,500 (47,300) | 24,500 (53,900) | |||

| Controller | OSP-P300MA | |||||

[ ]: Optional

*1. No. 40 spindle is optional.

*2. 20,000 min-1 with HSK-A63 only

*3. 20,000 min-1 with HSK-A100 only

*4. Super-heavy spindle motor rating is 20 min/cont (for heavy-duty cutting)

*5. 20,000 min-1 spindle motor rating is 30 min/cont

*6. Values differ with a matrix magazine. Please inquire.

*7. With MA-600HⅡ 20,000 min-1, the maximum tool diameter is limited depending on the spindle speed used.