大徑工件的穩定加工

即使對應不易裝夾的大徑薄壁件,或者不平衡的外形不規則工件等,均能實現穩定加工。

滑輪 |

軸承 |

閥體 |

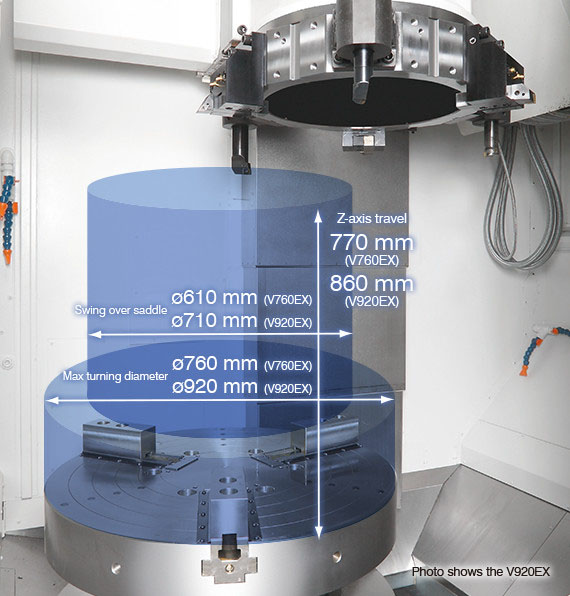

超大加工區域對應廣泛的加工需求在節省空間的同時,實現廣泛的加工區域。擁有足夠的空間(最大迴轉直徑:ø800mm/V760EX、ø1,000mm/V920EX),即使異形工件也可實現裝卡,滿足用戶廣泛的加工需求。

|

優秀的高剛性結構實現強力、高精度加工在高剛性、高減振性的大型床身上安裝了堅固的箱型立柱。

|

立式車床的特性,實現高精度穩定加工工件可依靠自重與卡盤基準面無縫緊貼,確保穩穩卡緊工件。可有效抑制因夾緊力造成的工件變形,所以也可實現從超薄工件到大直徑、重工件的高精度、高穩定性加工。此外,手動裝夾需要夾具的異形工件時,也無需支撐工件,因此裝卸十分方便。 |

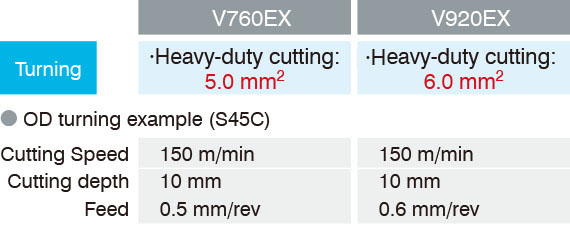

加工能力(實測值)

|

強力銑削實現工序集約

可安裝更強力、更多的刀具

1台機床即可完成車削和鑽孔、立銑加工,且對應的加工種類廣泛。

與舊機型相比動力刀具主軸功率得到大幅提高,可進一步實現強力加工和工序集約多元化。

最大限度減少與相鄰刀具干涉的刀架,可在12個刀位全部安裝銑削刀具。

依靠一次裝卡進行從車削加工到銑削加工的全部過程,可減少半成品保管空間及工序間的待工時間。

另外,可排除安裝工件時的裝卡誤差,提高了加工精度。

用廣泛豐富的生產形態推動製造現場的變革

1台2用的高生產效率 (2SP-V760EX、2SP-V920EX)

標準的R機(右)與採取左右對稱結構的L機(左)一體化,用1台數控設備驅動的雙主軸規格 2SP-V760EX、2SP-V920EX。

標準的R機(右)與採取左右對稱結構的L機(左)一體化,用1台數控設備驅動的雙主軸規格 2SP-V760EX、2SP-V920EX。

通過1、2工序的連續加工,縮短準備時間。通過減少中途半成品等,用最小化的佔地空間完成最大化的生產效率。

此外,由於採用了左右分離結構,不受其他軸的加工振動影響,可實現穩定的加工

- 可對應機器人行走距離最短化的狹窄生產線組線。

VIDEO:

機床規格:

| Item | Unit | V760EX | 2SP-V760EX | |||

| L | M | L | M | |||

| Capacity | Max turning diameter | mm (in.) | ø760 (29.92) | |||

| Max swing diameter | mm (in.) | ø800 (31.50) | ||||

| Swing on carriage | mm (in.) | ø610 (24.02) | ||||

| Max work length (height) | mm (in.) | 770 (30.31) | ||||

| Max workpiece weight (w/ chuck) | kg (lb) | 500 (1,100) [When limited to 1,000 kg/200 min-1] | ||||

| Height from floor to spindle nose*1 | mm (in.) | 1,085 (42.72) | ||||

| Travel | X-axis travel | mm (in.) | 390 (15.35) | |||

| Z-axis travel | mm (in.) | 770 (30.31) | ||||

| C-axis travel | Degrees | − | 360 (minimum control angle 0.001) | − | 360 (minimum control angle 0.001) | |

| Spindle | Spindle speed | min-1 | 20 to 2,000 | |||

| Spindle speed ranges | 2 auto ranges (2-speed motor coil switching) | |||||

| Spindle nose shape | JIS A2-11 | |||||

| Spindle bore diameter | mm (in.) | ø92 (3.62) | ||||

| Spindle front bearing diameter | mm (in.) | ø160 (6.30) | ||||

| Turret | Turret type | V12 | M-V12 | V12 + V12 | M-V12 + M-V12 | |

| No. of tools | 12 | L/M: 12 | 12 + 12 | L/M: 12 + 12 | ||

| OD tool shank dimensions | mm (in.) | □25, □32 (1, 1-1/4) | ||||

| ID tool shank diameter | mm (in.) | ø40, ø50, ø63 (1.57, 1.97, 2.48) | ||||

| Milling tool | Milling tool spindle speed | min-1 | − | 4,000 | − | 4,000 |

| Milling tool spindle torque | N-m | − | OSP:57.8/33.1 (25min/cont) FANUC:70/30 (inter/cont) |

− | OSP:57.8/33.1 (25min/cont) FANUC:70/30 (inter/cont) |

|

| Milling tool speed range | − | Infinitely variable | − | Infinitely variable | ||

| Feedrates | Rapid traverse X, Z-axis | m/min (fpm) | X: 24 (78.74), Z: 24 (78.74) | |||

| Rapid traverse C-axis | min-1 | − | 20 | − | 20 | |

| Cutting feedrate X, Z-axis | mm/rev | 0.001 to 300.000 | ||||

| Motor | Spindle drive | kW (hp) | 30/22 (40/30) (30 min/cont) | 30/22 (40/30) (30 min/cont) × 2 | ||

| Milling tool spindle motor | kW (hp) | − | OSP: 7.5/4.3 (10/5.7) (25 min/cont) FANUC: 5.5 (cont) |

− | OSP: 7.5/4.3 (10/5.7) (25 min/cont) FANUC: 5.5 (cont) |

|

| Axis drive motors | kW (hp) | OSP X: 3.5 (4.7), Z: 4.6 (6.1) FANUC X: 4.0 (5.3), Z: 4.0 (5.3) |

OSP X: 3.5 (4.7), Z: 5.2 (6.9) FANUC X: 4.0 (5.3), Z: 4.0 (5.3) |

OSP X: 3.5 (4.7), Z: 4.6 (6.1) FANUC X: 4.0 (5.3), Z: 4.0 (5.3) |

OSP X: 3.5 (4.7), Z: 5.2 (6.9) FANUC X: 4.0 (5.3), Z: 4.0 (5.3) |

|

| Coolant pump motors (50 Hz/60 Hz) | kW (hp) | Turret: 0.25/0.25 (0.3/0.3) shower: 0.37/0.55 (0.5/0.7) | ||||

| Machine Size | Machine height*1 | mm (in.) | 3,489 (137) | |||

| Required floor space (length × width)*2 | mm×mm (in.) | 1,842 × 2,732 (72.52×107.56) | 3,680 × 2,732 (144.88×107.56) | |||

| Machine weight | kg (lb) | 8,500 (18,700) | 8,700 (19,140) | 17,000 (37,400) | 17,400 (38,280) | |

| CNC | OSP-P300LA, FANUC 0i-TF | |||||

*1. Machine height and center height may become taller depending on attached cylinder type

*2. Including tank, not including operation panel

| Item | Unit | V920EX | 2SP-V920EX | |||

| L | M | L | M | |||

| Capacity | Max turning diameter | mm (in.) | ø920 (36.22) | |||

| Max swing diameter | mm (in.) | ø1,000 (39.37) | ||||

| Swing on carriage | mm (in.) | ø710 (27.95) | ||||

| Max work length (height) | mm (in.) | 860 (33.86) | ||||

| Max workpiece weight (w/ chuck) | kg (lb) | 1,200 (2,640) [When limited to 2,000 kg/200 min-1] | ||||

| Height from floor to spindle nose*1 | mm (in.) | 1,150 (45.28) | ||||

| Travel | X-axis travel | mm (in.) | 485 (19.09) | |||

| Z-axis travel | mm (in.) | 860 (33.86) | ||||

| C-axis travel | Degrees | − | 360 (minimum control angle 0.001) | − | 360 (minimum control angle 0.001) | |

| Spindle | Spindle speed | min-1 | 20 to 1,250 | |||

| Spindle speed ranges | 2 auto ranges (2-speed motor coil switching) | |||||

| Spindle nose shape | JIS A2-11 | |||||

| Spindle bore diameter | mm (in.) | ø110 (4.33) | ||||

| Spindle front bearing diameter | mm (in.) | ø200 (7.87) | ||||

| Turret | Turret type | V12 | M-V12 | V12 + V12 | M-V12 + M-V12 | |

| No. of tools | 12 | L/M: 12 | 12 + 12 | L/M: 12 + 12 | ||

| OD tool shank dimensions | mm (in.) | □25, □32 (1, 1-1/4) | ||||

| ID tool shank diameter | mm (in.) | ø40, ø50, ø63 (1.57, 1.97, 2.48) | ||||

| Milling tool | Milling tool spindle speed | min-1 | − | 4,000/3,000 (inter/cont) | − | 4,000/3,000 (inter/cont) |

| Milling tool spindle torque | N-m | − | OSP: 125.6/42 (inter/cont) |

− | OSP: 125.6/42 (inter/cont) |

|

| Milling tool speed range | − | Infinitely variable | − | Infinitely variable | ||

| Feedrates | Rapid traverse X, Z-axis | m/min (fpm) | X: 24 (78.74), Z: 24 (78.74) | |||

| Rapid traverse C-axis | min-1 | − | 20 | − | 20 | |

| Cutting feedrate X, Z-axis | mm/rev | 0.001 to 300.000 | ||||

| Motor | Spindle drive | kW (hp) | 30/22 (40/30) (30 min/cont) | 30/22 (40/30) (30 min/cont)×2 | ||

| Milling tool spindle motor | kW (hp) | − | OSP: 5.6 (7.5) (cont) FANUC: 5.5 (7.3) (cont) |

− | OSP: 5.6 (7.5) (cont) FANUC: 5.5 (7.3) (cont) |

|

| Axis drive motors | kW (hp) | OSP X: 3.5 (4.7), Z: 5.2 (6.9) FANUC X: 4.0 (5.3), Z: 5.0 (6.7) |

||||

| Coolant pump motors (50 Hz/60 Hz) | kW (hp) | Turret: 0.28/0.46 (0.37/0.61) shower: 0.39/0.62 (0.52/0.83) | ||||

| Machine Size | Machine height *1 | mm (in.) | 3,693 (145.39) | |||

| Required floor space (length × width) *2 | mm×mm (in.) | 2,252 × 2,845 (88.66×112.01) [3,302 × 2,845 (130.00×112.01)]*3 | 4,500 × 2,845 (177.17×112.01) | |||

| Machine weight | kg (lb) | 11,400 (25,080) | 11,700 (25,740) | 22,800 (50,160) | 23,400 (51,480) | |

| CNC | OSP-P300LA, FANUC 0i-TF | |||||

*1. Machine height and center height may become taller depending on attached cylinder type

*2. Including tank, not including operation panel

*3: With ATC specs